Hybrid Vehicle Air Conditioning System

Hybrid electric vehicle (HEV) implements dual ac compressors to support the normal operation of air conditioning system. One is electric compressor which is driven by brushless electric motor. The other is belt drive compressor which is attached to the vehicle engine. The traditional mechanical compressor is used as a backup when the power battery run out of juice, or when electric compressor is broken.

Therefore, HEV a/c system is more complicated and has many pipelines. Its working principle and internal refrigerant pressure is the same as traditional vehicle air conditioning systems. The main difference between them lies in the compressor:

◆ The traditional automobile compressor is driven by the engine through the belt. Its cooling performance is achieved by the ECU through adjusting the swash plate angle of the compressor. The hybrid compressor is driven by an electric motor. HCU (Hybrid Control Module) controls the motor speed to achieve high refrigerant performance, thus providing passenger cabin with cool air.

◆

Electric air-conditioning compressors use high voltage (HV) to drive the motor to run.

◆ when the vehicle engine is idling, belt drive compressor can only provide low refrigeration output, while electric compressors can promise steady-state cooling efficiency.

Novel Electric Compressor Designed for AC System on Hybrid Vehicles

When it comes to the purpose of the air con system on HEV, we should be aware of that the a/c system is used not only to cool the passenger cabin, but for battery thermal management. It’s clear that the A/C does matters a lot to the vehicle, its riders and battery pack. Its performance will become increasingly essential in the near future.

As a crucial core component of air conditioning system in hybrid electric vehicles, electric compressor plays an essential role in improving the performance of the A/C system. With the mass adoption of HEV around the world, manufacturers were all seeking to upgrade compression technology used by earlier generation hybrids, and utilize more efficient electric compressors. We have seen great improvement in compressor design, upgradation in motor technology, and development in advanced & reliable compressor technology.

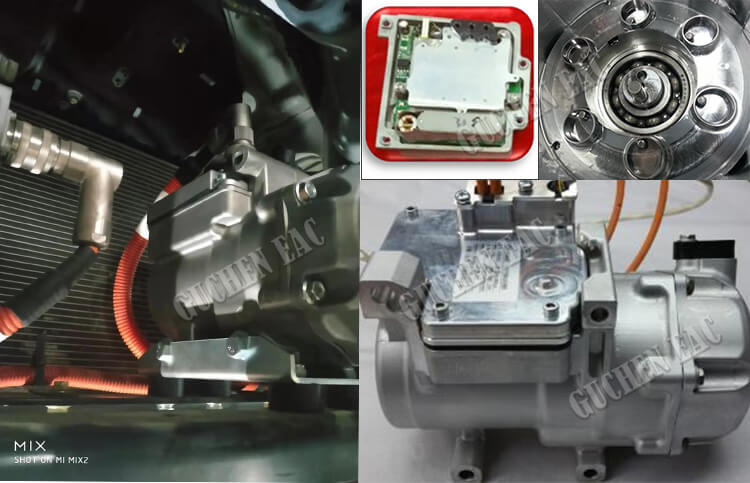

◆ Microprocessor-based control

The main control components of

electric ac compressors are microprocessors and inverters. The microprocessor receives the compressor target speed command from the controller to provide the required power for the motor; in addition, it feeds back the actual motor speed information and provides the current to the air conditioner controller for closing control.

◆ Variable speed drive

From the last paragraph, we know that today’s electric motor speed can be altered continuously depending on the cooling demand. Here comes another question: what intelligent system is applied to change the motor speed, thus improving motor efficiency.

It is Variable Speed Drive!

The efficient variable speed drive technology provides up to 30% energy saving. Just thinking about what a great deal of energy consumption it controls only by altering the electric compressor speed. Variable speed drive is a powerful innovation to increase your hybrid vehicle range by reducing energy utilization to drive the A/C.

More newer hybrids have move to

variable-speed electric scroll compressor. As its installation position is not restricted by the belt connection, the compressor unit can be installed in any position of the HEV.

◆ Brushless electric motor

The brushless DC electric motor and compressor are completely sealed inside the same casing. It drives the compressor, and enables the air conditioning system to continue operating, even when the HEV engine isn’t on. It is with a wide speed range, and can work at an optimum speed to satisfy the real time temperature demands, highly efficient. It is really a great innovation to use permanent magnet brushless electric motor in electrically supported compressors for hybrid vehicles.

All of this contributes to energy efficient HV AC system.

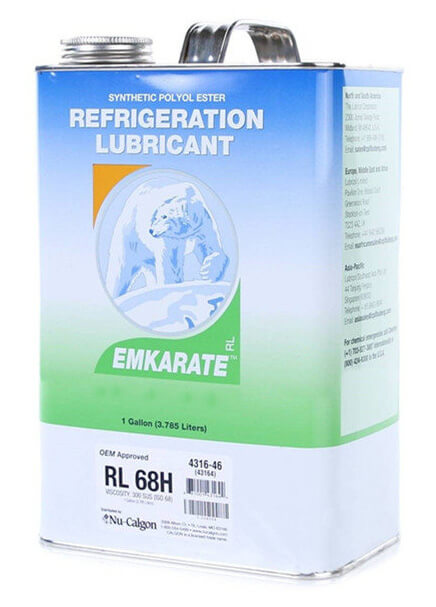

◆ Electric Compressor Oil

Do select the correct specific type of refrigerant oil what's recommended/identified by the manufacturer.

Refrigerant oil is used to lubricate the HV compressor. Hybrid vehicles with high voltage A/C compressors require

pure non-conductive POE (Polyol Ester) refrigerant oil in the system. We know that the HEV a/c compressor is directly connected with high DC battery voltage (above 300V). A very small voltage leaks will cause lethal shock to anyone coming into contact with it. That’s why it is so critical to select compressor oil with non-conductive property in the hybrid air conditioning systems.

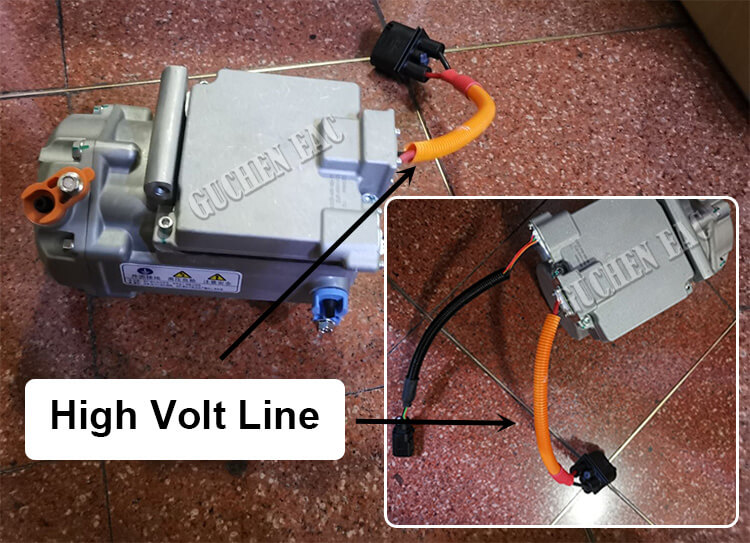

◆ High Voltage (HV) Line

People should be aware of some safety-related norms while handling voltage-carrying conductors. In a high voltage system above 60V DC, the need for contact protection becomes mandatory. When it comes to serve HV compressor, one of the basics is identifying a high voltage line. Generally, cables and connectors that are colour-coded orange (a visual warning) are high voltage. Taking

Guchen EAC's high voltage compressor for example, there are 3 cables entering the compressor, two black cables and one orange cable. The orange cable is HV cable, indicating a high voltage line.