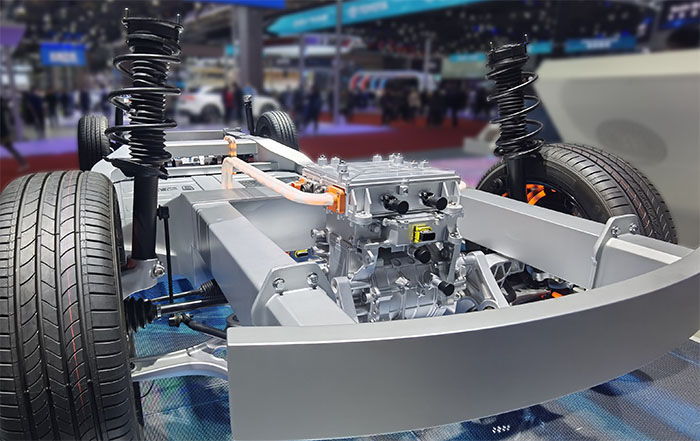

Electric vehicles are now widely used in different industries. The battery thermal management system (BTMS) in electric vehicles is an important aspect of vehicle design. Batteries are sensitive to temperature and require a cooling system to keep them at appropriate levels.

Electric Vehicle BTMS

The battery thermal management system (BTMS) is a system that maintains the battery temperature within a safe range. This is important because if the temperature gets too high or too low, it could damage the EV's battery. The BTMS uses a refrigeration cycle to cool the battery when necessary and keep it at an optimal operating temperature. In addition to keeping your EV's battery cool, a system that performs well also reduces the need for recharging during hot weather. This means less time and money spent charging your vehicle.

How to achieve:

The main purpose of the EV battery cooling system is to remove heat from the battery pack. This can be done by three means: air cooling, liquid cooling and direct cooling

1) The air-cooling mode rely on natural airflow through the vehicle to provide adequate cooling for the batteries.

2) Liquid cooling generally uses an independent refrigeration cycle to heat or cool the power battery. At present, this method is the mainstream of cooling. For example, Tesla and Volt both use this cooling method.

3) The direct cooling system eliminates the cooling pipeline of the power battery, and directly uses refrigerant to cool the power battery.

Core component:

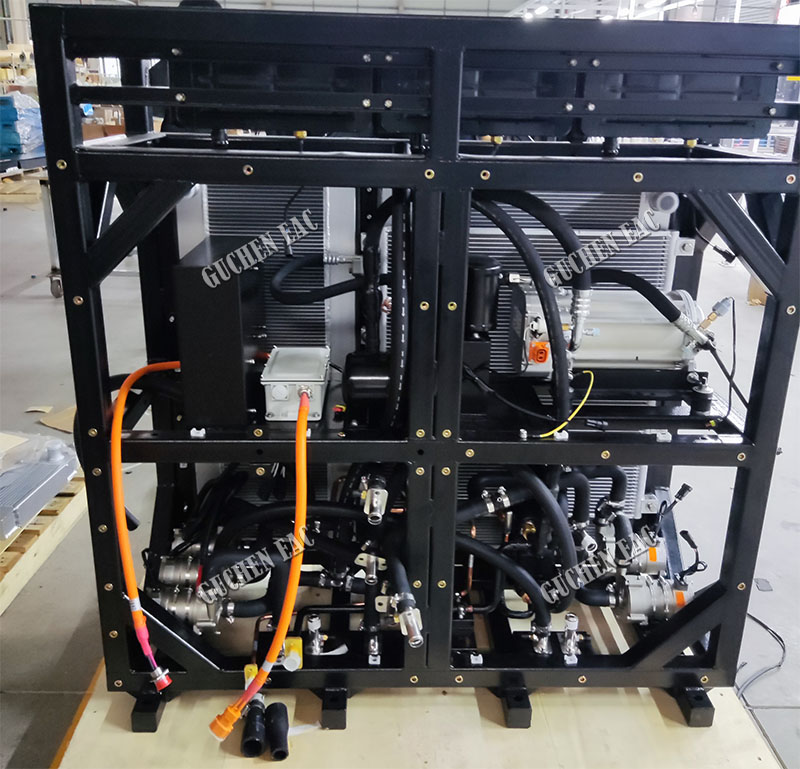

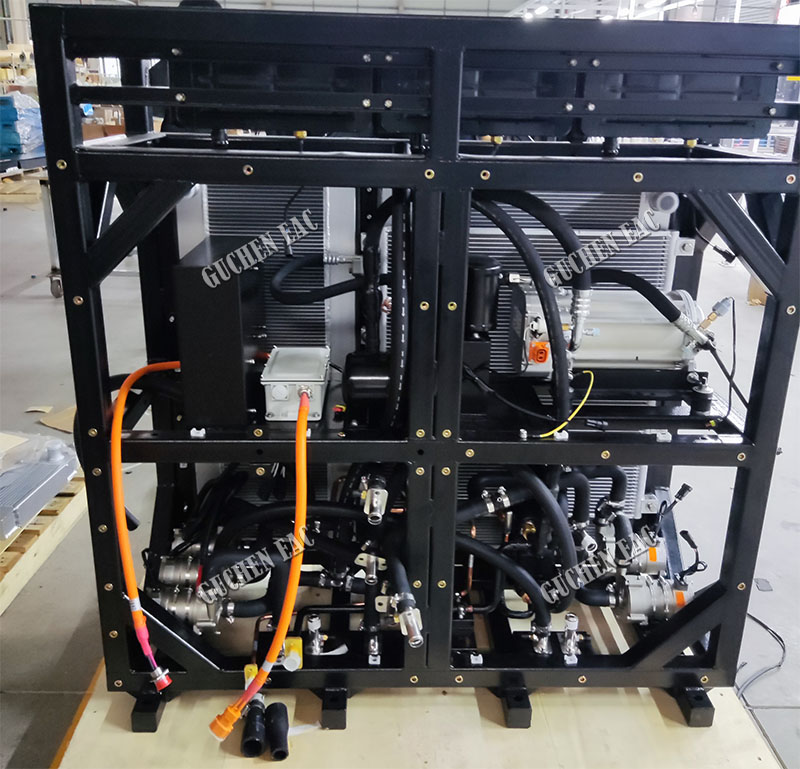

Electric Bus Battery Thermal Management System is a complex system that regulates the temperature of the battery pack to ensure safe operation. The BTMS consists of many components that work together to ensure proper operation of the bus.

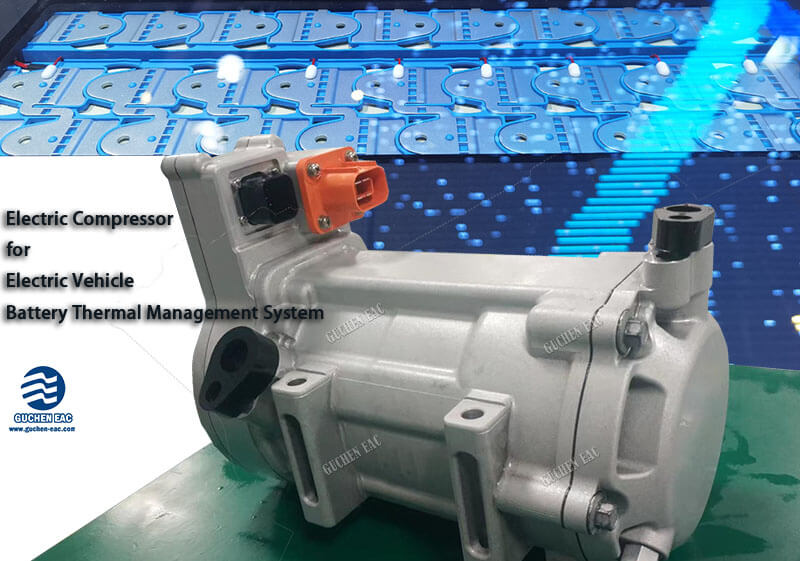

The most important component in the electric bus battery thermal management system is the compressor. The compressor is used to circulate coolant through the radiator and back into the battery pack.

The automotive industry has made a lot of advancements in recent years. One such innovation is the electric compressor which is used to power vehicles’ air conditioners. This technology has made it possible to reduce emissions and improve fuel efficiency by up to 20%. The electric compressor is also an integral part of the BTMS for electric vehicles. It cools down the battery pack and prevents it from overheating, overcharging, overdischarging and other unfavorable conditions.

The main purpose of an electric compressor: The role of an electric compressor is to help cool down your battery array. Batteries produce heat when charging and discharging, and this can damage them over time. An electric compressor helps remove this excess heat from your battery array so that it can perform at its best level possible. The ideal charge temperature range for batteries is around 32-114 degrees Fahrenheit (0-45 Celsius).

Battery’s ideal temperature ranges:

| STATUS |

TEMPERATURE RANGE |

| Discharge Temperature |

-4° F to 130° F |

| Charge Temperature |

32° F to 114° F |

If the temperature gets too high then this will eventually lead to failure of your batteries. By using a compressor you can ensure that your batteries remain within their optimum range at all times, which ensures maximum life span and reliability.

This is done by providing cooling air through its fan and passing it over the battery cells at a speed that depends on their surface area and their coefficient of heat transfer with air. A typical BTMS may include one or more compressors depending on the size of the system being designed. Therefore, the development of

high-efficiency electric air conditioning compressors has become an important topic in recent years.

Electric compressor in electric construction machinery BTMS

Electric compressor in electric construction machinery BTMSCompressor type:

The most common type is electric scroll compressor. It is widely used in automotive BTMSs due to their high heat exchange efficiency and quiet operation. The basic structure of an electric scroll compressor consists of an inverter, electric motor, bearing seat, rotating scroll, fixed scroll, oil-gas separator, and protective cover.

Why using scroll compressor in BTMS:

◆ Electric scroll compressor has good performance, compact structure and light weight.

◆ The power of the motor can be adjusted according to the demand of the refrigerant flow, so that it can save energy effectively.

◆ The

electric scroll compressor has a low start-up current, which reduces the starting current and eliminates the need for an auxiliary device such as a starter motor.

◆ The motor can be more effective in adjusting its speed according to the load requirements and reducing the speed range between high and low speeds, so as to reduce energy consumption at low speeds.