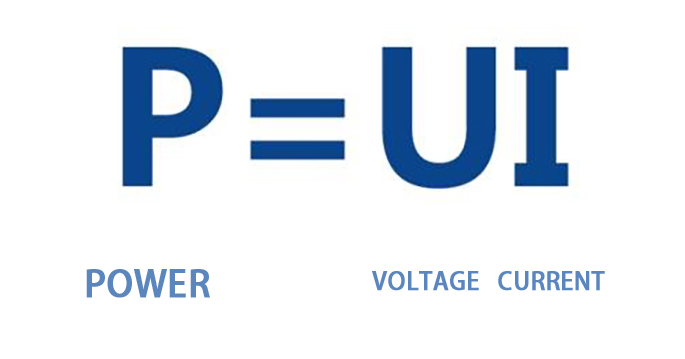

The fast charging technology, which can provide up to 350kW, is a great feature that allows the EV owners to charge their cars quickly. The fast charging ability of an electric car depends on the voltage and current. The higher the voltage and current, the larger the charging power will be. To improve the charging speed, there are two technical routs:

1) Simply by increasing the current flow. This has been done by increasing the current rating of the cables, which is a good step forward. However, there are limitations to this approach. The maximum current rating of any EV charging cable is limited by its resistance and its temperature rise during operation. Higher current will however lead to faster degradation of the batteries, as well as higher heat generation from the charger itself.

2) By updating to a higher voltage platform.

Keeping the current constant, and the charging power will double while increasing the voltage. That is, the peak charging speed is doubled, and the charging time will be greatly shortened. In addition, under the same charging power, if the voltage is updated to a higher level, the current can be reduced. Therefore, the charging cable does not need to be so thick, and the resistance heat energy consumption will also be reduced.

It is easier to reach higher efficiency at higher voltages, than at higher current.

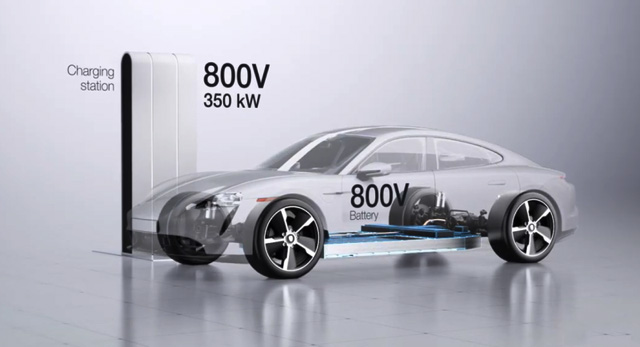

800V High Voltage Platform

At present, the voltage range of the EV HV electrical system is generally 230V-450V, collectively referred to as the 400V system; and with the application of fast charging, the voltage range will reach up to 550V-930V, which is called the 800V system. The core of fast charging technology is to increase the charging power. As detailed above, increasing the current means thicker and heavier wiring harnesses and more heat generation. While the charging voltage increase has greater design freedom, which directly promotes the conversion from 400V platform to 800V high voltage platform.

The benefits of 800V high-voltage platform include:

◆ Reducing energy consumption;

According to Joule's law, in a high-voltage system, the reduced current reduces the power loss of the entire system and improves efficiency.

◆ Increasing cruising range;

If the current remains the same, the motor drive efficiency will increase, thereby increasing the cruising range and reducing battery costs.

◆ Reducing the weight of the high-voltage wiring harness;

Under the same power condition, the increase of the voltage level can reduce the current on the high-voltage wiring harness, making the wiring harness thinner, thereby reducing its weight and saving installation space.

Doubling the voltage brings a higher upper limit of charging power, lower copper loss, and higher power density of the motor inverter. According to a study by Huawei, fast charging using the 800V high-voltage mode supports 30%-80% SOC maximum power charging, while the low-voltage high-current mode can only perform maximum power charging at 10%-20% SOC, and the charging power drops very rapidly in other intervals. It can be seen that the 800V high voltage mode can support fast charging for a longer period of time. The higher operating efficiency of the vehicle means that when the current remains constant, the higher the battery voltage, the greater the motor power, and the higher the efficiency of the motor drive. Therefore, the 800V high-voltage platform can easily achieve high power and high torque, as well as better acceleration performance.

However, there are still some problems that need to be solved before we can widely use the 800V high voltage system. One of them is the

high voltage and high current required by the AC compressor used in EV air conditioning system. The existing AC compressors are mostly designed for 230V-450V electrical system. Therefore, they cannot meet the requirements of 800V EVs and battery packs with higher voltage requirements.

Compared with core components such as batteries and chassis, air-conditioning compressors may be an inconspicuous automotive component. However, with the electrification of automobiles, in addition to providing a comfortable cabin temperature, automobile thermal management has also become an important guarantee for driving safety. Electric compressors, as high-voltage components that directly drive electric vehicle air conditioning systems, have become extremely critical.

As the technology continues to advance, the demand for 800V compressor is rising. Guchen EAC has developed two models of 800V ac compressor with 27cc displacement and 34cc. The compressor can be applied to multiple EV HV parts such as the cockpit, BMS, and electric motor thermal management, which greatly improves thermal management efficiency; its cost is 20% lower than that of their counterparts. All-round NVH optimization to realize the quiet driving experience. At the same time, it covers two different displacements of 27CC\34CC and a product matrix of 600V~840V, which can meet the climate control needs of EV manufacturers.

◆

Variable speed control: The speed of the electric compressor can be switched freely within the range of 1000rpm-6500rpm, to meet the differentiated cooling demands during high-voltage charging and daily driving, and minimize energy consumption.

◆

Unique scroll structure and winding method: Structurally, the fixed and orbiting scrolls are not worn during the working process, which greatly improves the reliability of high-speed operation. The 800v scroll compressor has good working characteristics, and its performance is mainly affected by its own compression ratio and suction pressure, with wide discharge pressure. The compressor can always be running at a high energy efficiency ratio.

◆

Better efficiency: The high axial and radial flexible structure ensures that the sealing of the axial gap and radial gap won’t be reduced due to friction and wear. Therefore, the 800V scroll compressor has reliable and effective sealing, and its COP does not decrease with the increase of running time, but slightly increases;

Guchen EAC mainly produces electric compressors for new energy vehicles, including low voltage compressors and high voltage ones. We also provide solutions for heat dissipation and thermal management systems for automobiles and other automotive parts manufacturers. Guchen compressors have been widely used in electric buses, heavy equipment, trucks and passenger cars.