Electric forklifts have become the preferred choice of lift truck operators because they are easier to use, safer and more environmentally friendly than conventional ones. They use electric motors for propulsion. These motors are powered by batteries. The batteries used by these machines must be cooled to prevent overheating and damage to the cells in order for them to work efficiently over a longer period of time. Otherwise, they may not last as long as you would like them too!

In an electric vehicle, the battery is located under the floor of the vehicle. This is done for safety purposes and to increase storage space in the vehicle—the batteries can weigh several hundred pounds each. A cooling system helps keep the temperature of a battery within safe limits so that it will last longer and not damage other components in the e-forklift.

What is Battery Cooling System?

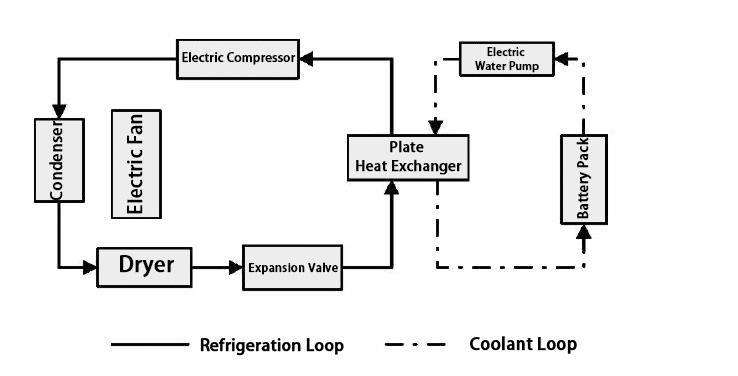

The basic principle behind this system is that it uses a chiller in the refrigeration loop. The refrigeration loop consists of a compressor, a condenser, a liquid receiver, two expansion valves, a chiller, and an evaporator.

The

electric ac compressor takes in refrigerant gas under pressure and compresses it into a hot high-pressure vapor. The hot high-pressure vapor then passes through the condenser where it cools down by giving off its heat to the ambient air temperature or any other cooling medium such as water or oil. The resulting low-pressure gas is then sent back to the compressor where it gets compressed into another hot high-pressure vapor that passes through the evaporator which gives off its heat to an ambient medium such as air or water thereby cooling down the refrigerant gas yet again. Now we have our desired cold refrigerant gas again ready to be compressed by

EV compressor into yet another hot high-pressure vapor so that this cycle can repeat itself over and over again.

Battery Cooling System is a Must-Have for Any Electric Forklift Battery

Battery cooling systems are an important part of electric construction machinery because they can help to extend the life of the battery. When batteries are used in extreme temperatures, they may not function properly and may even fail.

Battery cooling systems are designed to prevent this from happening by keeping batteries at a constant temperature while they are charging and discharging. The heat generated by charging or discharging causes batteries to expand, so it is important to ensure that they do not get too hot.

Benefits of battery cooling system include:

◆ Extends Battery Life

The battery cooling system is designed to keep your batteries at the optimal temperature range, which results in a longer lifespan of the battery.

The optimal temperature range is between 20 and 30 degrees Celsius. This is important because it's the most efficient operating range for your battery. The cooler they are kept during operation, the longer they'll last before needing replacement or recharging--and that saves money!

◆ Prevents Overheating, Reducing risk of fire

Battery cooling systems reduce the risk of fire by reducing the internal temperature of the battery. This in turn reduces the amount of energy being converted into heat, and reduces the rate at which this heat is transferred to surrounding areas. This helps prevent overheating and increases overall battery life.

◆ Prevents Excessive Heating During Charging

Batteries generate heat during charging and discharging processes because of chemical reactions inside them. This heat needs to be removed from the batteries in order for them to function properly, which is done by using coolant fluids such as water or anti-freeze solutions that are circulated through pipes within the battery housing unit (BHU).

-----------------------------------------------

The

battery thermal management system (BTMS) is a critical component of all electric vehicles and its performance directly affects the battery’s cycle life, safety, and durability. The BTMS is designed to protect the battery from overcharge, over discharge, overheating or undercooling. It also monitors the battery temperature, voltage and current conditions to ensure safe operation of the vehicle.