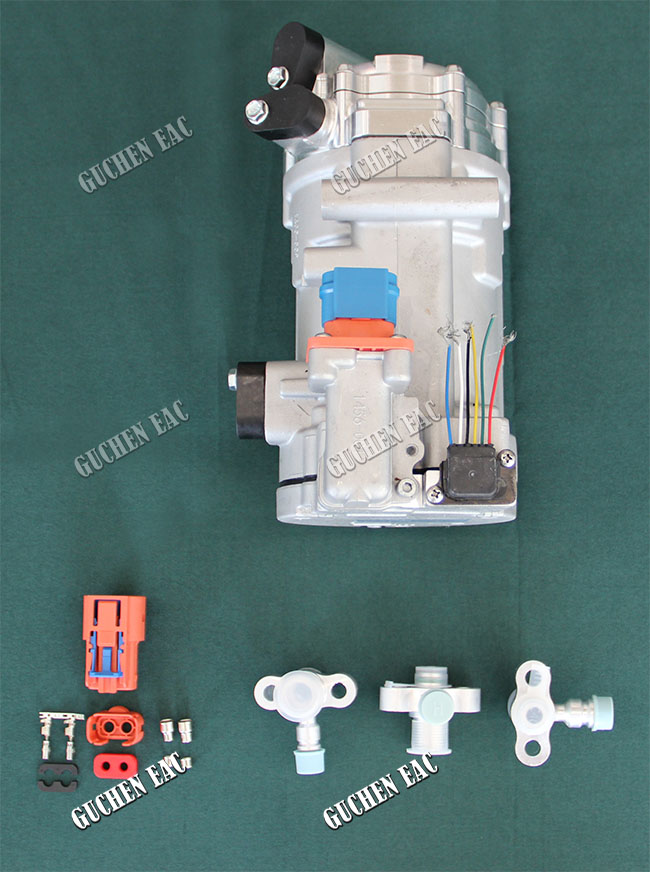

Model: HP34A350

Brand: Guchen EAC

Type: Heat pump

Rated Voltage: 350V DC (DC200~400V)

Cooling capacity: 7.6KW

Heat source: Air (air-source heat pump compressor)

Key part in heat pump system: four-way valve

Function: to cool or heat electric vehicle applications, with better heating performance in cold winter days.

Compared with the PTC heating technology currently used on the market, Guchen gas injection electric compressors have significant energy-saving advantages.

The innovations of Guchen

Enhanced Vapor Injection heat pump EV compressor are as follows:

1. Integrated Design Innovation

The motor and compressor are integrated into a single unit

a) to reduce energy wastage and increase reliability.

b) to make the whole unit compact, elegant, and beautiful.

c) to reduce the installation space and facilitate maintenance work.

d) to reduce product volume and improve heat dissipation performance.

PS: Heat dissipation enhancement is of great significance for improving the overall efficiency of the fuel cell.

Guchen Heat Pump DC 350V electric air conditioning compressor integrates BLDC motor, refrigerant, inverter and other electric components into one unit. This design saves space and construction cost for customers. Meanwhile, it also improves heat exchange efficiency and reduces noise pollution during operation.

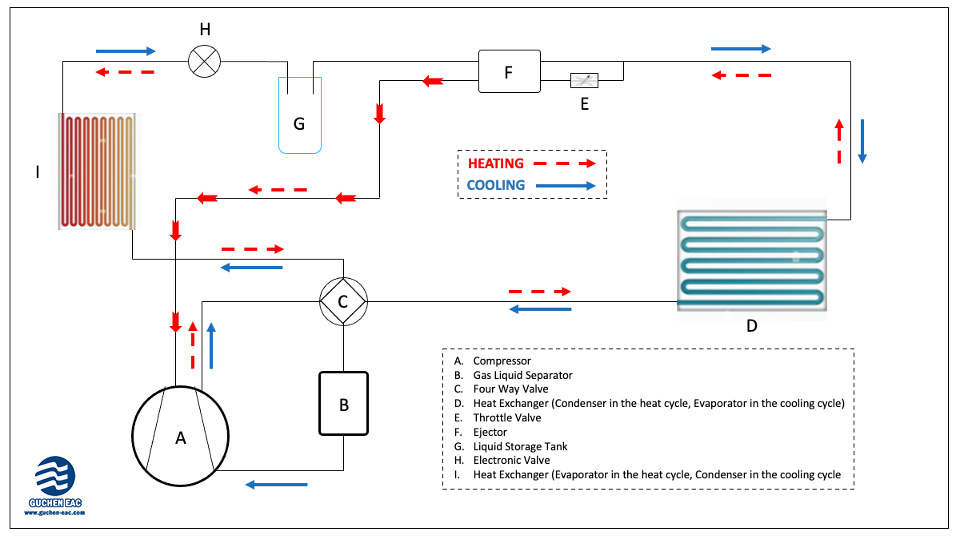

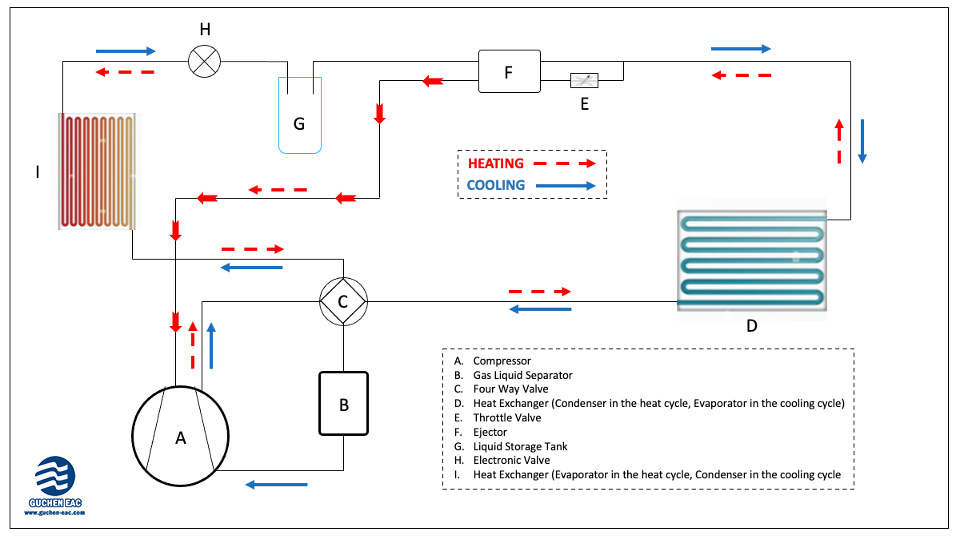

2. Gas Injection Innovation

The gas injection type heat pump is an energy-saving air conditioning compressor with a high efficiency and low noise. HP34A350 compressor has adopted the gas injection method, which makes it more energy-efficient and high-performance than other products.

Vapor Injection Cycle --- Copyright @Guchen EAC

Vapor Injection Cycle --- Copyright @Guchen EAC The

electric scroll compressor with vapor injection introduces intermediate pressure refrigerant into the compressor chamber to realize intermediate cooling of the compressor, reduce the superheated discharge temperature, and realize the stable operation of the electric compressor under the condition of large compression ratio.

In this way, the stable heating of the heat pump system at an ambient temperature of -20℃ can be realized. Guchen low-temperature heat pump compressor with increased enthalpy can provide 4-5KW heating capacity at an ambient temperature of -20℃ in actual vehicle operation, and maintain a system operating COP of 2.8 or higher.

b) The pressure ratio is high and low noise, which makes it suitable for electric passenger vehicles with high requirements on cabin heating in winter days. It has been widely used in electric vehicles such as electric car, truck, van, RV, etc., where there are strict heating energy requirements at low temperatures.

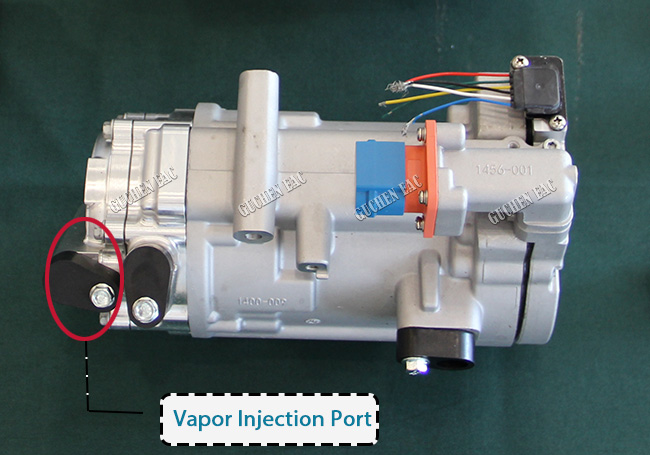

3. Two-stage Compression Innovation

Heat pump compressor is equipped with a second suction port. The refrigerant gas flowing into the compressor is mixed with the saturated refrigerant gas, which increases the refrigerant flow rate and increases the enthalpy difference of the main cycle refrigerant. This design innovation upgrades the compression process of ordinary electric compressors to two stage, and effectively improves the compression efficiency.

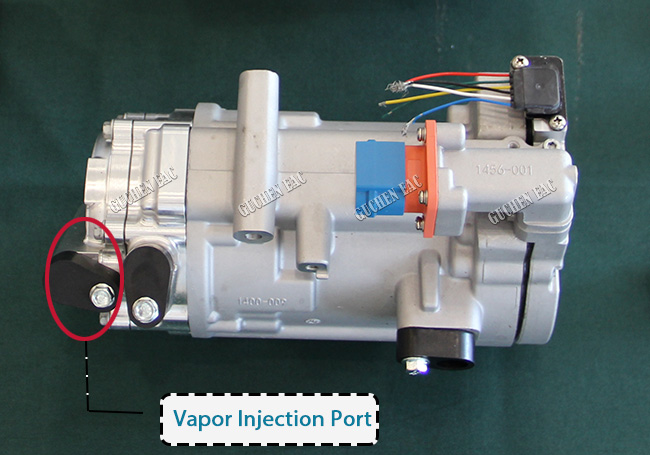

Vapor injection port of HP34A350 model --- Copyright @Guchen EAC

Vapor injection port of HP34A350 model --- Copyright @Guchen EAC

HP34A350 model uses two stages of compression to achieve higher efficiency and lower noise while maintaining overall system efficiency at a high level.

a) Electric vehicle ac compressor with two-stage compression technology can increase heat exchange efficiency and reduce power consumption by 20%.

b) The air inlet temperature of each stage can be adjusted by changing the speed of the compressor. With this innovation, it can ensure that each stage operates at optimal efficiency at different working conditions.

c) High COP makes it the most efficient electric compressor currently available in EV air conditioning system.

The heat pump air-conditioning compressor for electric vehicles developed by Guchen EAC adopts two-stage compression technology to improve the efficiency of the heat pump cycle and solve the problem of large power consumption for heating and defrosting of electric vehicles in extremely cold regions.

Conclusion

In the next decade, electric vehicles will become the mainstream of the automotive industry.

For electric vehicles, the cruising range is the biggest bottleneck restricting its wide application, and the operation of the air conditioning system consumes a lot of energy. Therefore, it becomes more urgently to update EV AC system to a more efficient one that requires less power to operate.

The Guchen low-temperature vapor-injection heat pump electric compressor system for is widely used in electric vehicles, which can greatly help solve the problem of electric vehicle cruising range in winter, improve the acceptance of electric vehicles among global consumers. It totally adapts to the development strategy of the global automobile industry.