Abstract

1. Introduction

◆ How to Extend the Cruise Range?

2. What is Vapor Injection Heat Pump System

◆ Two Stage Compression Refrigeration Cycle

--How to achieve two-stage compression?

--Step by step analysis

◆ Flash Tank Vapor Injection Technology

--Novel design

--Where the "vapor" come from?

--How it works

--Benefits

◆ Air Source Heat Pump for Heating in EVs in Cold Winter

Introduction

New energy vehicles, especially pure electric vehicles, are currently developing rapidly in the world, and China is stepping up its efforts to support the development of new energy vehicles. In the past five years, the production and sales of electric vehicles in China have almost always increased at a multiple rate. In the next ten years, electric vehicles will become the mainstream of the automotive industry.

However, the cruise range of EVs is still not parallel to that of traditional vehicles. What’s more, electric vehicle’s cold-weather cruising range suffers a significant decrease due to the thermal loads of air conditioning system.

How to Extend the Cruise Range?

One the one hand, For electric vehicles, the cruising range is the biggest bottleneck restricting its wide application, especially in cold climate. The operation of the air conditioning system will greatly reduce the cruising range of electric vehicles.

On the other hand,

electric AC compressor, as the core of electric vehicle air conditioning system, incorporates the electric motor, controller and compressor unit into a whole. It has great automatic control (thermostatic control on vehicle air-conditioning system) performance, and realizes information exchange with the vehicle control system.

The higher the COP value of electric AC compressor, the more the reduction of climate control loads; thus the EV AC system would be greatly improved to extend the driving range.

Therefore, for automakers/car OEMs, using

effective electric compressors will definitely do great favor in

◆ reducing the thermal loads on EV’s AC system;

◆ extending cruising range;

◆ increasing the market penetration of EVs.

◆ much helpful for the practicability of EVs.

That is why the Novel Air-source Vapor-injection Heat Pump System are developed!

Tesla Model Y with a heat pump

Vapor injection heat pump systems can in particular be used to respond to the climate control demand of EV air conditioner loads in cold regions. Heat pump heating does is a promising way in satisfying the energy demand of EVs in winter days.

Taking a typical electric vehicle with a range of 300km and 35kw of electricity as an example, using a heat pump air conditioner to reduce the heating power to 1kw, the cruising range is reduced to 233km, which is much higher than the 192km of PTC Heating. It can be seen that heat pump air-conditioning is one of the few effective technologies to ensure low energy consumption heating when there is no breakthrough in power batteries.

Extension Reading:

Benefits of Heat Pump Air Conditioner on EV Battery Life

What is Vapor Injection Heat Pump System

The system we will talk about in details next can be fully described as “a two-stage scroll compressed air source heat pump system coupled with a flash tank indirect vapor injection”.

◆ Two Stage Compression Refrigeration Cycle

Simply put, add a flash tank between the condenser and compressor to form a closed loop. This loop enters the electric compressor directly without passing through the evaporator. It guarantees the return air volume, and stables the heating efficiency of automobile HVAC system in cold winter days.

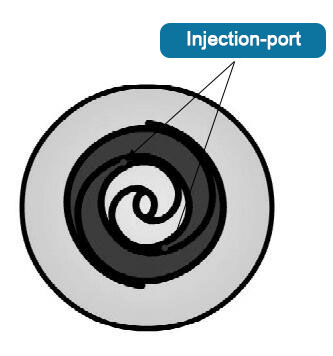

How to achieve two-stage compression: By opening an injection hole in the appropriate position on the scroll, and adding a suction circuit to

1)increase the refrigerant mass flow rate;

2)increase the air enthalpy difference of the refrigerant.

The novel design enables to upgrade the

electric scroll compressor from single-stage compression to two-stage compression. It improves the compression efficiency, and widens the application and operating range of air-source heat pump system.

The two-stage compression is realized in a single compressor through the design of vapor injection technology.

In order to explain more clearly, we can analyze this process step by step:

The first step: The compressor receives the Energy A absorbed by the evaporator from the air, and starts to compress it.

The second step: Turn on the vapor injection auxiliary loop, and vapors pass through compressor.

The third step: The part of Energy A being compressed by the compressor is mixed with the incoming vapor. This process will continue until the working chamber of the compressor is separated from the inlet port. At this time, the vapor and Energy A are fully mixed and become a new Energy B.

The fourth step: After the compression chamber is separated from the vapor injection port, Energy B are went into two-stage compression, and finally the Energy B enters the condenser to exchange heat with water.

◆ Flash Tank Vapor Injection Technology

Vapor injection technique refers to electric scroll compressor with vapor injection for air-source heat pump system. The technology makes it possible for

heat pump scroll compressor to operate at cold temperature.

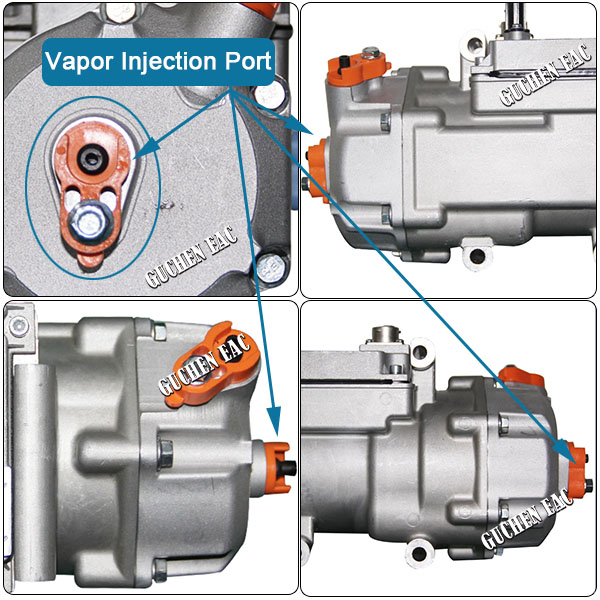

Novel design: the vapor injection scroll compressor is designed with two return pipe ports, which is the biggest difference in appearance from non-heat-pump electric compressors.

Guchen EAC vapor injection heat pump compressor

Guchen EAC vapor injection heat pump compressor

: vapor are generated by the flash evaporator in the air-source heat pump system. The flash tank has a pipeline connected to the scroll compressor. That is how the vapor flows along the pipeline from the flash evaporator to the compressor. The whole vapor injection process is controlled by electromagnetic valve located in the loop from the flash evaporator and compressor.

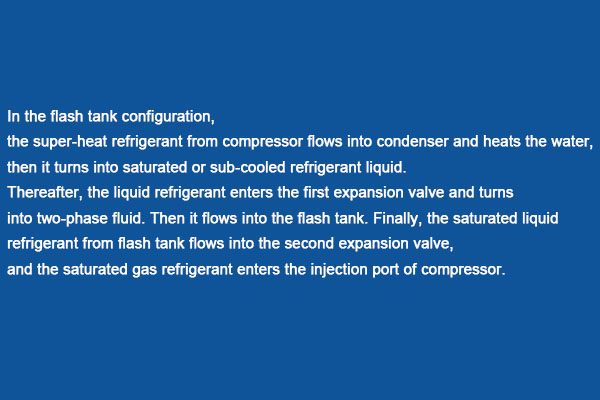

How it works: in the flash tank vapor injection auxiliary loop, the refrigerant that exits the condenser is throttled first. The two-phase refrigerant enters the flash tank. Thereafter, the gas (saturated gas = vapor) and liquid are separated. The vapor is injected into the scroll compressor.

Benefits: When the flash evaporator supplies vapor to the compressor, it actually increases the subcooling degree of the liquid refrigerant before throttling, so that the liquid in the evaporator can better absorb heat in the air.

◆ It indirectly increase Energy A provided by the evaporator to the compressor.

◆ As vapor are injected to the scroll compressor, the quantity discharged to the condenser is greater, with improved heat exchange capacity. The higher the heat exchange efficiency, the larger the air enthalpy difference.

It is these two factors that enable the two-stage air-source heat pump system provide sufficient heating capacity even at low ambient temperatures.

◆ Air Source Heat Pump for Heating in EVs in Cold Winter

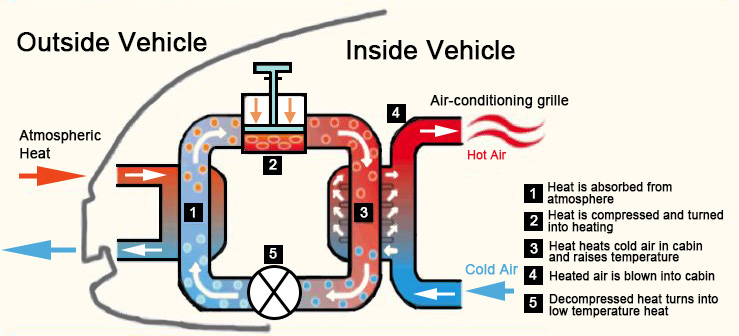

EV heat pump air-conditioning system uses air source heat pump technology for heating in winter, particularly in low ambient temperatures.

Its heating energy efficiency ratio can reach 2 to 3, much higher than that of PTC heating. It has good heating performance, which can significantly improve the battery life of electric vehicles in winter.

Air source heat pump with vapor injection technique is the best alternative to electric auxiliary heating systems, which is in line with the development trend of new energy vehicles, necessary for practicability and industrialization of EVs.

Air source heat pump with refrigerant injection has good temperature regulation ability. In winter, when the ambient temperature is minus 10℃, the EV heat pump air-conditioning system can control the cabin temperature at 25℃, which ensures passenger comfort. It can also provide a comfortable driving environment for electric vehicles with high efficiency at an ambient temperature of -10℃ to 40℃.

In the future, with 1) the optimization of the piping design of air-source heat pump system, 2) the gradual use of refrigerants with better heating performance and 3) the reduction of costs, there will be more and more applications of air energy heat pump heating systems in pure electric vehicles.