Electric vehicles (EVs) are becoming increasingly popular, but they do have a few limitations. One of the biggest issues is range anxiety: the fear of running out of battery power before reaching your destination.

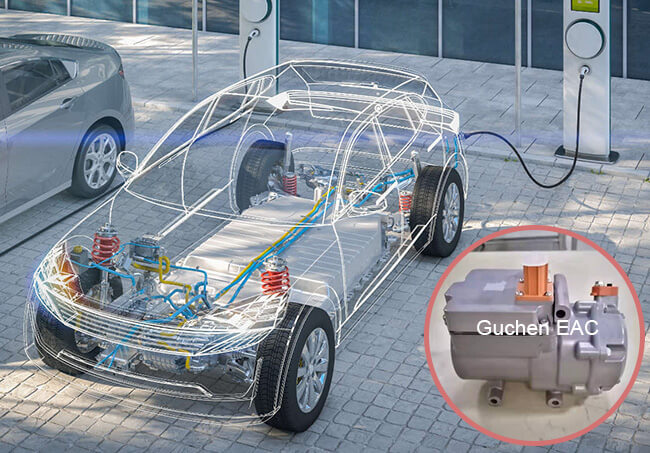

The range of EVs are currently limited by the life and performance of their batteries. Therefore, to extend the range of EVs, it is necessary to improve the battery performance and durability. One way to extend the life of EV batteries is to charge them with a lower charging current, which reduces stress on the cells and extends their life. The other way to increase the range is by improving the efficiency of the air conditioning system. The best way to improve the efficiency of EV AC system is to get a high-efficiency compressor for your air conditioning system.

Better Compressors Can Improve EV Range

Compressors are one of the biggest drains on an electric vehicle's battery, because they use up a lot of energy. A typical compressor uses up around 25% of all the electricity used by an EV during use. This is why it's important to get a

high-efficiency electric car compressor that can reduce that energy drain considerably.

A good quality HVAC compressor will be able to use less electricity so that more power can be freed up for other uses like heating and cooling, which means more freedom when driving around town or taking long trips across country!

Some original equipment manufacturers (OEMs) have designed certain components in order to extend battery life. For example, Toyota has designed an electric compressor with an integrated controller that allows it to operate at low speeds even when the load is high. This feature enables Toyota vehicles equipped with this compressor to reduce their power consumption while maintaining high levels of comfort during operation, thus prolonging vehicle range.

EV Air Conditioning Compressor Efficiency

The traditional model of the automotive air-conditioning system has been based on dedicated mechanical compressors driven by the engine. Though this method is considered to be simple and reliable, it has its own disadvantages such as power loss and large weight.

Due to the above mentioned disadvantages, most electric vehicle manufacturers and suppliers are looking for better alternatives. This is where

automotive electric compressors come in.

Challenge faced by eCompressors: The challenges of high-power electric compressors are mainly related to four aspects: 1) Low energy conversion efficiency; 2) High temperature operation environment; 3) Large cooling area requirements caused by large duty ratio requirements; 4) Poor reliability and life cycle problems caused by moisture accumulation on surfaces due to low operating temperatures. These problems have been gradually solved in recent years

With high standard compressor technology, it is possible to expect higher efficiency, better performance and longer mileage range in electric vehicles. One thing for sure is that the improvement of EV AC Compressor efficiency has great significance in improving EV range. In addition, it also affects other aspects such as energy consumption and CO2 emission.

Electric Compressor Efficiency is Complex: Compressor efficiency can be measured by calculating its COP (coefficient of performance), which is determined by dividing its output (in Btu) by its input (in watts). A higher COP means more energy is being transferred without using more electricity or fuel. Compressor efficiency can be affected by the compressor design (waste heat recovery etc.), compressor controls, drive motor, motor efficiency and other factors. But the most important factor affecting its performance is the control system of the

electric car ac compressor.

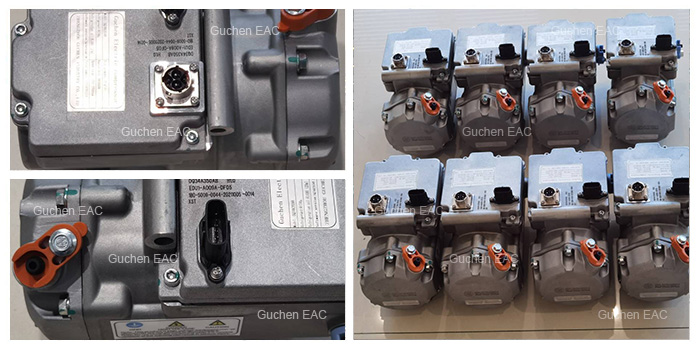

Compressor Control Systems - It can have a major impact on efficiency. They control the speed of the compressor motor by varying the amount of refrigerant entering it and therefore its capacity to compress air or gas. The system must be able to maintain a constant capacity over a wide range of conditions such as temperature, pressure and flow rate. The speed control device of Guchen HV compressor uses an intelligent control system to achieve intelligent control of the output power according to different working conditions.

Drive motor - The motor used has an effect on overall system efficiency as it converts electrical energy into mechanical energy for driving the compressor. The most common type of motor used in EV A/C system is DC brushless motor. DC brushless motors are more energy efficient, and also cost less.

Compressor design - A well designed compressor will have lower friction losses, higher volumetric efficiency and lower leakage losses. Waste heat recovery can also increase the overall efficiency of the system.

Taking

Guchen 800V electrically-driven compressor for example, it is well designed and boasts a high efficiency. It is built with a highly efficient motor and an optimized design. This allows it to deliver high performance at a low cost. The use of an electrical motor in this compressor makes it easy to install and maintain.

Otherwise, it uses a design that minimizes the amount of heat generated by the motor so it can run at higher efficiency levels. This means that electric vehicle air conditioner will use less electricity and work better!

Lastly, the 800V compressor has been designed with an oil separation system that separates oil from the refrigerant during the liquid state. This ensures that dirty oil does not contaminate clean refrigerant and cause damage to the compressor's seals and other components.