“Electric vehicles phase out PTC and use heat pump air-conditioning for heating in winter days more, which brings demand for heat pump electric compressors”

Two Heating Solutions for Electric Cars

Electric vehicle cabin cooling can be achieved by replacing the traditional clutch compressor with engine as the power source with electric compressor. As for heating, there are two main heating schemes designed for EV AC system currently.

One is to use the PTC electric heating device to provide heat for the passenger cabin.

The other is to use heat pump air conditioning system. Seeing from the perspective of energy consumption, because of its high efficiency, heat pump air conditioner saves much more energy. Global R&D institutions, and electric vehicle manufacturers are actively developing heat pump air conditioning systems. As the core component for EV cabin cooling and heating,

electric air conditioning compressor has also become a key research object.

PTC Heater Affects Battery Life

Electric car’s range will be reduced in cold weather, especially using lithium iron phosphate batteries. In addition to the characteristics of the battery itself, the use of air conditioner for heating (cooling) is also one of the important factors that affect the battery life.

At present, the most widely used heating method is

PTC heating, which is similar to a hair dryer. Hot air is emitted through the heating resistance wire, very power-consuming.

The early NIO ES8 has a dual PTC combination of 5.5kW in the front and 3.7kW in the rear. Calculated based on the 355 km battery life on full power for 10 minutes consumes 7km of the cruising range.

The heat produced by the PTC heating element when it is working, on the one hand, will be transferred by the fan into the cabin in the form of warm air; on the other hand, it will heat the power battery pack. In other words, the EV must not only provide warm air for the drivers and passengers, but also control the cells temperature inside the battery pack using heated antifreeze coolant. That is the reason for greatly reduced battery life in winter days.

Future Looks Bright for Heat Pump Air Conditioning Systems

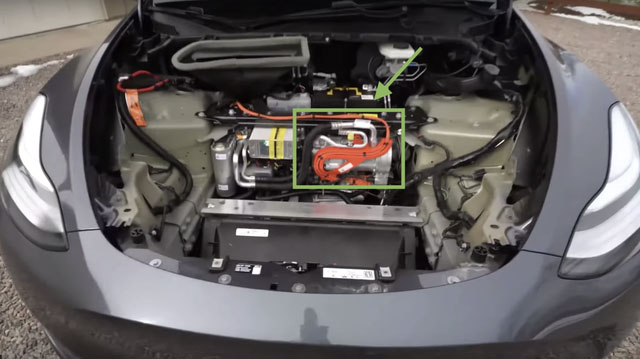

It was not long ago that Tesla added a heat pump air conditioner to the Model 3. The latest XPeng P5 of XPeng Motors is also equipped with a heat pump as standard. PTC air conditioners, a big power-consuming system, are gradually stepping off the stage of history.

Tesla Heat Pump HVAC System

There is a very important component in the heating and cooling process of the air conditioner, called the compressor.

For the electric AC compressor, when it is applied to the

heat pump system, there are the following differences from the conventional refrigeration system:

First of all, the heat pump system requires the compressor to have a larger speed range (600~8000rpm/min). In order to ensure that the compressor can be lubricated well at such a high speed, the ratio of lubricating oil to refrigerant often reaches 10% (The general air-conditioning refrigeration compressor is less than 2%).

Second, heat pump system is always used in a relatively low ambient temperature, as low as -20℃. At this temperature, the solubility of lubricating oil and refrigerant decreases; the specific volume of refrigerant increases; the effective suction quality decreases, so as the lubricating oil quality. The higher the compressor speed is, the more lubricating oil being required.

Third, compared to refrigeration, the suction pressure of heating conditions is lower, and the pressure ratio of the compressor is increased, so the discharge temperature of the

high voltage compressor will also increase, which may cause the failure of lubricating oil carbonization, and damage it in severe cases.

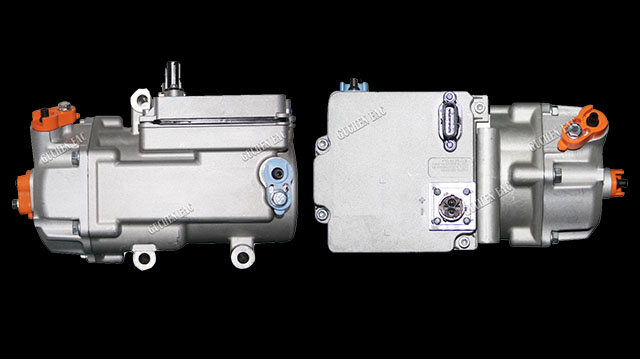

Heat Pump Electric Compressor Designed by Guchen EAC

Guchen EAC recently announced 3 heat pump electric air-conditioning compressors: 20cc, 27cc and 34cc. Among them, 34cc heat pump compressors have already been used in electric vehicles equipped with heat pump air conditioning systems. Guchen EAC's products have always been at the leading level in the industry, which not only meets the automotive industry's requirements for safety, comfort and energy saving, but also has precision, innovation and breakthroughs. Among them, the

electric heat pump compressor is the result of breaking the technical shackles of the industry.

The electric heat pump scroll compressor launched by Guchen EAC uses R134a as the refrigerant, which is widely used in air-conditioning refrigerants around the world. It is relatively mature and has a cost advantage. The R134a

heat pump scroll compressor has a small volume and an efficient and stable cooling/heating core. It not only provides an excellent working environment temperature for auto parts, but also provides a comfortable temperature driving space for vehicle users.