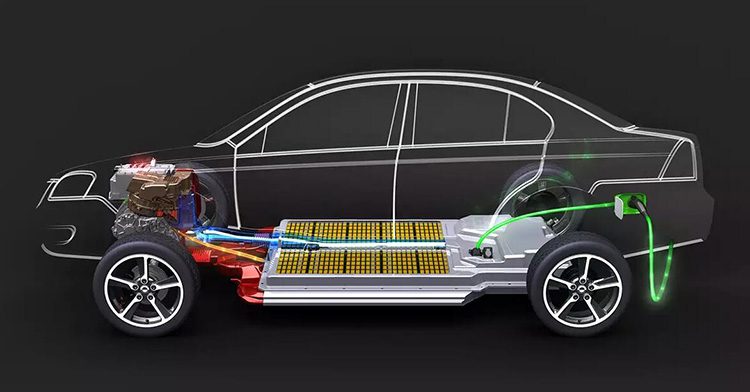

Both hybrid cars and pure electric cars have high voltage components. In pure electric vehicles, the components directly connected to the power battery are high voltage components, which are mainly distributed at the bottom of the car and the front cabin.

High-voltage components mainly include battery pack or fuel cell, battery management system (BMS), electric motor, motor control unit (MCU), power distribution unit (PDU), electric a/c compressor, DC/DC converter, on-board charger (OBC), EV charger, charging socket, PTC heater, and high-voltage wiring harnesses, etc. These components constitute the high-voltage system of the entire vehicle, of which the power battery, electric motor, and motor controller are the top three core components of new energy vehicles.

1. Battery Pack & Battery Management System (BMS)

Unlike traditional fuel cars, all-electric cars are powered solely by electricity, not the engine. The invest in battery electric vehicles is essential for cutting emission in the long term. Therefore, in order to avoid catastrophic impacts of climate change and reduce environmental pollution, the development of electric vehicles is actively supported by the government and states.

Current battery systems for electric cars typically have operating voltages of 200-600 volts. And its output current can reach 500A. Battery capacity directly affects the driving mileage of EVs, and also has an impact on charging efficiency & charging time.

At present, Lithium-ion batteries dominate markets in the global. Limited by current battery technology, most electric cars use lithium-ion batteries. Meanwhile, in order to reduce electromagnetic radiation generated by high-voltage components, electric vehicle high voltage systems adopt shielding design.

The battery management system (BMS), also called battery controller, is the core component of battery management and protection. Its function is to ensure the safe and reliable use of EV batteries, to control the charging and discharging of battery packs, and to report the basic parameters & fault diagnosis information to the vehicle control unit (VCU).

Tesla Battery Pack

2. Electric Motor & Motor Control Unit (MCU)

The electric motor converts electrical energy from the battery into mechanical energy to drive the car. It has a higher working efficiency (more than 85%) when compared with fuel vehicles which convert chemical energy of fuel combustion into mechanical energy. Therefore, compared with traditional vehicles, the energy utilization rate of EVs is higher. To a great extend, it can reduce the waste of resources.

The motor controller is a device that controls the energy transmission between the battery and the drive motor. Its main functions include vehicle idle speed control, vehicle forward (motor rotating in a forward direction), vehicle reverse (motor reverse rotation), DC/AC conversion, etc. It converts high voltage direct current to alternating current, and performs signal interaction with other modules on the electric car to achieve affective control to drive motor.

3. Power Distribution Unit (PDU)

Power distribution box is a device to distribute the high voltage power of the entire vehicle, similar to the electrical fuse box in the low-voltage circuit system. It is composed of many high voltage relays and fuses, with related chips inside it, to realize signal communication and ensure the safety of high voltage electricity.

It distributes the high voltage battery power to high-volt electrical equipment such as motor controller, drive motor, electric air conditioning compressor, PTC heater, and DC-DC converter. At the same time, the high voltage charging current imported from the AC or DC charging port is distribute to the battery in order to charge the battery pack.

4. On Board Charge (OBC)

OBC is a device that converts alternating current to direct current. Because the battery pack is a high voltage direct current power supply, when using alternating current for charging, the alternating current cannot be directly stored by the battery pack. Therefore, a OBC device is required to convert the high voltage AC to DC to charge the battery.

5. DC/DC

DC/DC is a device that converts high-voltage direct current to low-voltage direct current. There is no engine in electric cars, and the electricity source for the entire vehicle is no longer generators and storage batteries, but power battery packs and storage batteries. As the electrical equipment on electric vehicles is usually powered by low volt 12V or 24V, a DC/DC device is required to convert high voltage DC to low voltage DC, so as to maintain the power consumption balance of the entire vehicle.

Some DC/DCs are high voltage to high voltage conversions, to facilitate 1) fast charging, 2) connection to standard charging stations, 3) the reliability of BMS.

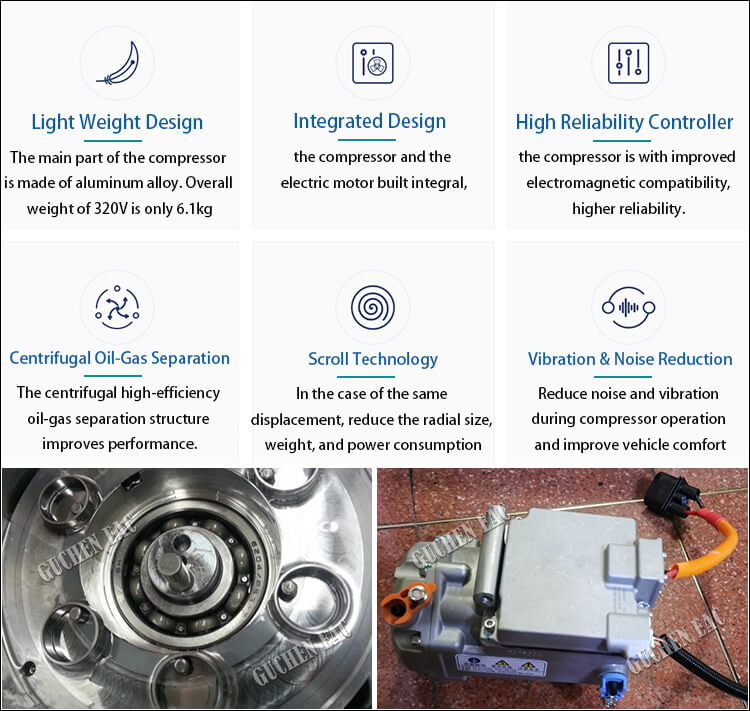

6. Electric AC Compressor

Electric scroll compressor for electric car air conditioner is mainly composed of moving scroll, fixed scroll, support bracket, anti-rotation mechanism, radial flexible mechanism, electric motor and inverter electric control part. It is the core of electric vehicle air conditioning system. It has the advantages of simple structure, low noise, light weight, stable operation and high efficiency.

7. PTC Heater

The heat source of traditional vehicle HVAC system is from the heat of the coolant introduced into the engine after cooling, which does not exist in new energy vehicles. Therefore, a special heating device is required. The device is called as PTC heater. When the ambient temperature is low enough, the battery pack needs certain amount of heat to work normally. At this time, PTC Heater is used to preheat the battery pack.

Nowadays, with the rapid research and development of e-compressor technology, the novel high-efficient heat pumps are developed and used to warm the vehicle cabin. See more information on Guchen EAC

heat pump scroll compressor.

8. High Voltage Cables

The high-voltage wiring harness connects the various components of the high-voltage system as a medium for high-voltage power transmission. Different from the low-voltage wiring harness system, these wiring harnesses are equipped with high-voltage electricity, which greatly affects the stability of the high-voltage system of the vehicle. The safety of high-voltage wiring harness should be taken into consideration when designing and operating the electric cars.