Advantages of CO₂ Refrigerant

1. Safety and Environmental Friendliness

As shown in Table 1, CO₂, being a natural refrigerant, is non-flammable, non-toxic, has no ozone depletion potential (ODP), and an extremely low global warming potential (GWP). These characteristics make it an ideal choice for environmentally friendly and safe refrigerant applications.

| Refrigerant |

R134a |

R1234yf |

R744 |

| Molecular Formula |

CF3CH2F |

CF3CF=CH2 |

CO2 |

| Standard Boiling Point /℃ |

-26.1 |

-30 |

-78.5 |

| Critical Temperature /℃ |

101.1 |

95 |

31.1 |

| Critical Pressure /MPa |

4.07 |

3.38 |

7.38 |

| GWP Value |

1430 |

4 |

1 |

| ODP Value ① |

0 |

0 |

0 |

| Safety Group ② |

A1 (Non-toxic,Non-flammable) |

A2L |

A1 (Non-toxic,Non-flammable) |

| Cost / (RMB/kg) |

48 |

400 |

6 |

| Examples of Guchen compressor models |

GC20A12 |

GC66B600 |

Under development |

Table 1: Key Parameters of Refrigerants

① ODP: Ozone Depletion Potential

② ASHRAE Safety Classification System

A: Low toxicity;

1, 2L, 2, 3: Flammability levels.

1: Non-flammable.

2L: Slightly flammable with low flame propagation velocity.

2: Flammable.

3: Highly flammable.

Unlike synthetic refrigerants, using CO₂ in automotive air conditioning systems eliminates the need for refrigerant recovery during vehicle scrapping. CO₂ is also widely available and low-cost, offering significant cost advantages over refrigerants like R1234yf.

2. Exceptional Heating Performance

Heat pump systems often experience reduced heating performance in low-temperature environments. This occurs due to the decreased density of refrigerant gas at low temperatures, leading to lower mass flow rates, and because the suction pressure of the system must be kept positive by limiting compressor speed.

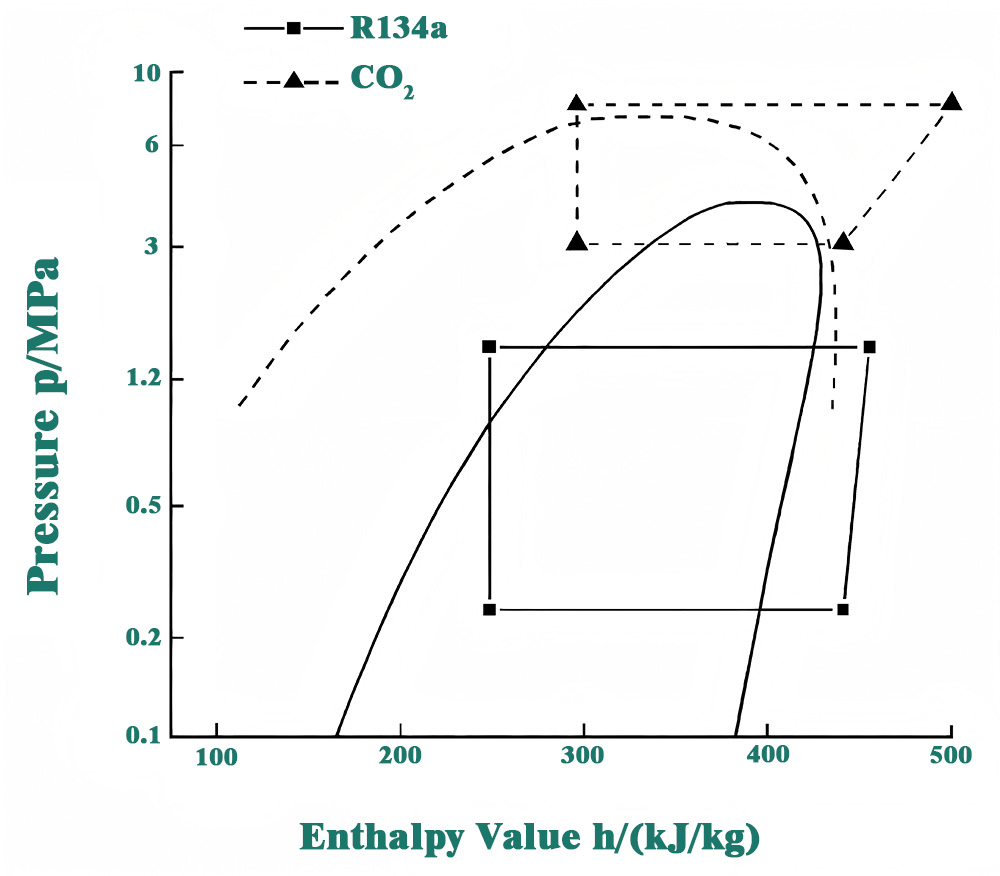

Figure 1: Pressure-Enthalpy Diagram for R134a and CO2 Systems

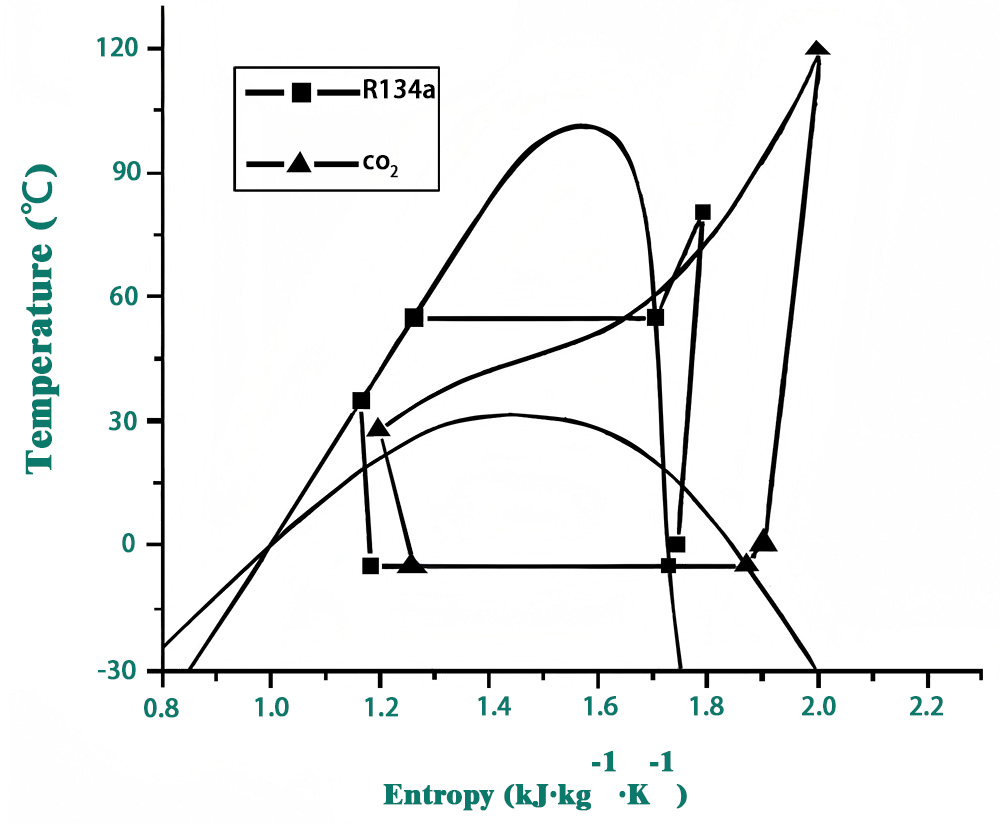

Figure 2: Temperature-Entropy Diagram for R134a and CO2 Systems

Figures 1 and 2 illustrate that CO₂ has much higher gas density and evaporation pressure compared to R134a or R1234yf, enabling it to maintain superior heating performance even in low-temperature conditions.

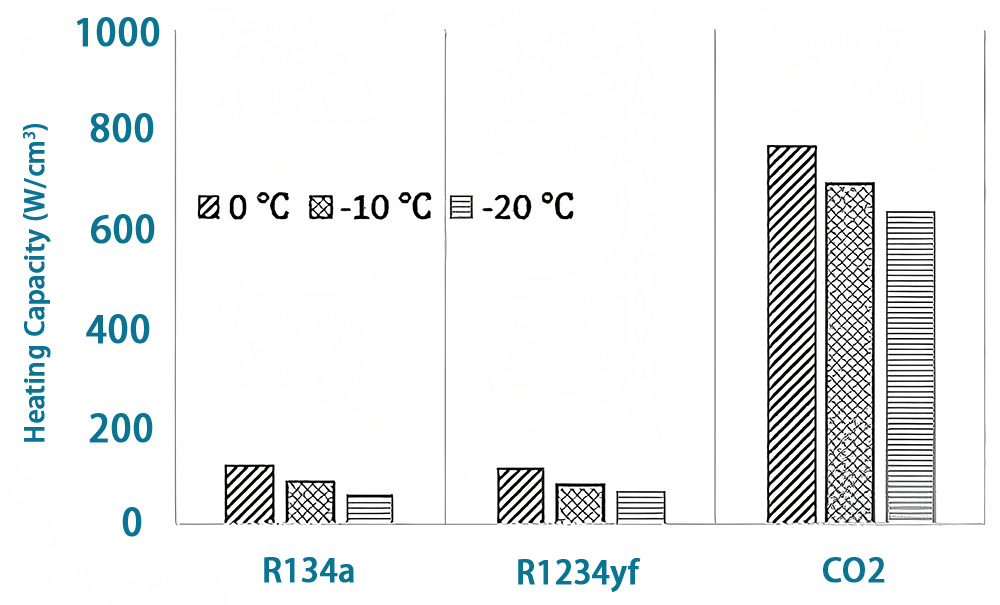

Figure 3 shows the heating capacity (in terms of compressor displacement in cm³) for three types of refrigerants at different ambient temperatures. The heating capacity of the CO2 system at different ambient temperatures is 7 to 11 times greater than that of the R134a or R1234yf systems. Especially at low temperatures, the CO2 system still maintains a high heating capacity,

allowing heat pump systems using CO2 as a refrigerant to be applied in regions or seasons with lower temperatures. Furthermore, such high heating potential theoretically enables electric vehicles using CO2 as a heat pump refrigerant to eliminate the typically used electric heaters, thereby improving energy efficiency and reducing system costs.

Figure 3: the heating capabilities of various refrigerants based on the displacement of the compressor

Related reading:

Two-stage Heat Pump Systems with Vapor Injection Scroll Compressor for EVs at Cold Temperatures

Challenges of CO₂ Refrigerant

1. Lower Efficiency in Cooling and Heating

CO₂ systems typically operate in transcritical states, where the refrigerant is supercritical on the high-pressure side. The significant energy loss during the expansion throttling phase results in lower cycle efficiency.

Studies indicate that CO₂ systems have 20–40% lower cycle efficiency than R134a or R1234yf systems, with this disadvantage becoming more pronounced at higher ambient temperatures. Lower efficiency leads to reduced energy performance, increasing fuel consumption in internal combustion vehicles or electricity consumption in electric vehicles.

However, in extremely low temperatures (below -10°C), the efficiency of CO₂ heat pumps surpasses that of R134a or R1234yf systems. This is because the latter systems require auxiliary electric heating due to their limited heat pump capabilities, significantly reducing heating efficiency. Advanced technologies, such as ejectors and expansion devices, are being explored to enhance CO₂ cycle efficiency, but these are still in experimental stages and face technical hurdles that hinder immediate commercial application.

2. High Lifecycle Carbon Emissions

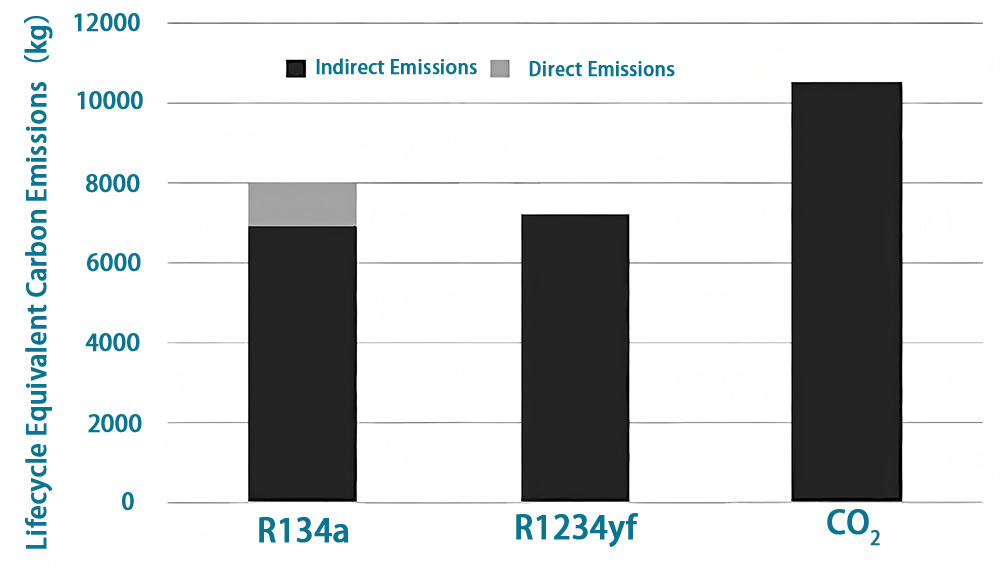

Lifecycle carbon emissions of automotive air conditioning refrigerants include direct and indirect emissions. Direct emissions occur from refrigerant leakage during charging, operation, maintenance, and end-of-life recovery, while indirect emissions arise from energy consumption during system operation and refrigerant production/transportation.

While CO₂ has a negligible GWP value, its low energy efficiency during operation results in significantly higher lifecycle carbon emissions compared to R134a or R1234yf. This is particularly relevant in regions like China, where the advantages of CO₂ heat pumps at low temperatures are less impactful due to temperate and subtropical climates.

Figure 4: Lifecycle Carbon Emissions of Different Automotive Air Conditioning Refrigerants in China

3. Costs and Leakage Issues Associated with High Operating Pressure

CO₂ systems operate at pressures exceeding 15 MPa, with a high-pressure differential often surpassing 12 MPa, and discharge temperatures reaching over 160°C. These extreme conditions necessitate the redesign of all refrigerant loop components to withstand such high pressures and temperatures, significantly increasing component costs.

Although CO₂ itself is inexpensive, components such as

compressors, heat exchangers, refrigerant pipelines, separators, valves, and pressure sensors are more expensive than their counterparts in R134a or R1234yf systems, raising overall system costs by at least ¥2500.

Additionally, CO₂'s smaller molecular size increases leakage risks through hoses or connectors under high-temperature and high-pressure conditions. While specialized sealing materials for CO₂ systems have been developed, their effectiveness remains suboptimal, requiring more frequent refrigerant refills to maintain system performance.

4. Safety Concerns

Although CO₂ is non-toxic and odorless, leaks into the vehicle cabin could pose health risks. CO₂ concentrations as low as 1% can cause discomfort and drowsiness, while levels of 2% can lead to headaches and concentration loss. At 5%, unconsciousness or even fatality may occur.

To mitigate risks, vehicles using CO₂ refrigerants must be equipped with CO₂ sensors. An alternative design involves indirect heat exchange, where refrigerant loops are confined to the engine bay and cooled air is circulated into the cabin. However, this approach reduces heat exchange efficiency, further lowering system cooling performance.

The high pressures of CO₂ systems also increase safety risks during development, testing, and maintenance.

Outlook for CO₂ Refrigerant Applications

Based on the analysis of CO₂'s characteristics and current technological limitations, Guchen Industry concludes that large-scale adoption of CO₂ automotive air conditioning systems is unlikely in the short term for the following reasons:

◆ Efficiency and Carbon Emissions: The lower energy efficiency of CO₂ systems increases lifecycle carbon emissions, conflicting with global goals for energy conservation and carbon neutrality.

◆ Climate Suitability: CO₂ heat pumps excel in cold climates, but the advantages are less significant in regions with moderate climates, such as most of China.

◆ Cost and Safety Challenges: High-pressure operation leads to increased costs, leakage risks, and safety hazards that require further technological advancements to address.

That said, CO₂’s natural properties, including non-flammability, low toxicity, zero ozone depletion, and cost advantages, combined with its exceptional heating potential, hold promise for future adoption. As technology evolves, CO₂-based automotive air conditioning systems may become viable for a broader range of applications.