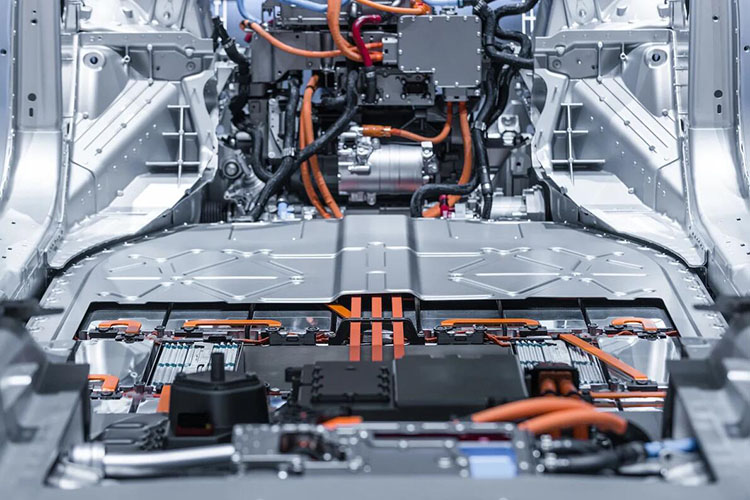

New energy electric vehicles are now a hot word in the automotive industry. In recent years, the production and sales of new energy electric vehicles have shown a sharp rise, and more and more people have begun to accept and use electric vehicles as a means of daily travel.

Many people know it only about the brand, but they may not know much about other more information, such as the composition of automotive high-voltage circuits, air conditioning systems, and electric compressor over-current protection devices.

Compared with traditional gasoline vehicles using 12V or 24V low-voltage systems, electric vehicles use high-voltage electrical systems above 300V. High-voltage and high-current provide sufficient power for the vehicle while also testing the safety of high-voltage electrical appliances on the vehicle. This also requires that the high-voltage components on the electric vehicle should have a

high-voltage interlock device. As a

well-known manufacturer of electric compressors, Guchen EAC will introduce to you today the knowledge of new energy vehicles-the role of high-voltage interlocks!

High-Voltage Interlock Loop (HVIL)

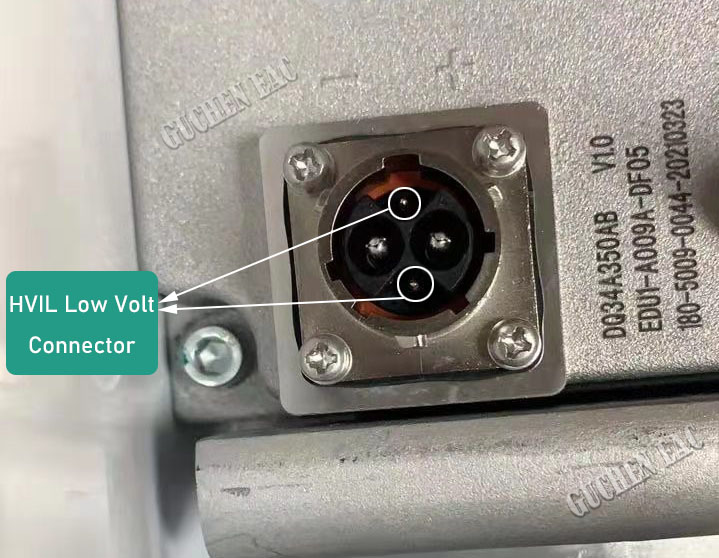

High voltage interlock loop is a safety circuit specially designed to monitor the integrity of high voltage circuits. It is a current and voltage loop mechanism. As a key part of the overall vehicle electrical safety strategy, interlock is used to detect tampering or opening of the high voltage connection system, thus preventing energizing high-voltage power supplies until all access doors are closed. In electric vehicles, HVIL consists of one or more low voltage loops in series and control module. Taking electric car air conditioning system for example, its

high-voltage interlock device is with one low voltage loops, which monitors HVIL circuit.

Theoretically, all high voltage devices like high voltage connectors, manual service disconnect (MSD), should have safety interlocks on access doors.

◆ A high-voltage interlock loop in the

high-voltage electrical circuit to prevent any danger caused by improper disconnection of the high voltage connector on an active high-voltage system.

◆ An interlock device integrated into the

MSD to prevent electrical arcs from occurring during unmating & mating.

High voltage connection systems in a new energy vehicle mainly include rechargeable battery pack, on-board charger (OBC), DC/DC converter, PTC heater, power distribution unit (PDU), air-conditioning compressor and other subsystems that operate at high voltages. Electric vehicle air conditioning system is driven by an electric compressor, wherein the electric compressor is an

interlock device mounted inside its high voltage connector, to ensure safe startups and shutdowns.

More Information on the Interlock Device in an Electric AC Compressor

Main function: As the electric compressor is mounted on electric vehicle to a high voltage power source, the interlock device is used for detecting disconnection of the high voltage connector that connects the air-conditioning compressor.

Why is it a must-have device for high voltage compressors: The electric compressor is connected to high voltage battery by a high voltage connector. Since there is a risk that an accident like an electric shock will occur if the HV connector is disconnected, a high-voltage interlock device is necessary to provide the connector with an interlock loop to help detect the poor connection of the HV connector due to open circuit.

Guchen EAC High-voltage Interlock Design

Guchen EAC high voltage electric compressors are designed with interlock functions based on the safe design concept, guiding the development direction of the entire electric compressor industry. Choosing Guchen EAC means choosing to rest assured!