With the growing popularity of new energy vehicles (NEVs), integrated vehicle thermal management (IVTM) becomes the main focus. It is an incremental market that grows with the increased

electric vehicle uptake. It is predictable that with the rising penetration rate and improved performance of NEVs, the future market size and value of global automotive thermal management is huge. The market size of global automotive thermal system (including a/c system) was approximately at USD 46.4 Billion in 2019. Taking China as an example, it is expected that the sales of NEVs will reach more than 5.5 million units in 2022. The penetration rate will reach about 25% as the thermal management market has risen on an unprecedented scale.

Changes in Electric Vehicle (EV) Air Conditioning System

As is known to all, thermal management directly affects the overall performance (battery safety, lifespan, charging and discharging times, etc.) of EVs. Its importance to the entire vehicle is self-evident. Meanwhile, the development of NEVs also poses a major change to the thermal management system (TMS). For instance, the air conditioning system undergoes great changes due to the transformation of power mode.

Compressor

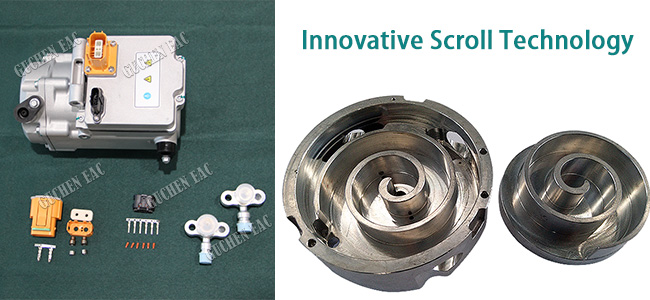

NEV air conditioners use

electrically-driven compressors which adopt the innovative scroll technology. Electric scroll compressors have almost no clearance volume, no suction valve and less gas leakage, which can give full play to its advantage of high volumetric efficiency.

Electric scroll type compressors are also featured by low vibration noise and light weight, being the most widely-used compressor in EV air conditioning systems.

EV Heating in Winter

NEVs have no engine therefore its a/c system cannot use the engine as a stable heat source for heating in cold winter days. At present, PTC electric heater is most widely used to warm the vehicle cabin. When warm air is turned on in winter, the efficiency of electrical resistance heater is low, which greatly reduces battery power and cruising range (which can be reduced by more than 50%), seriously affecting the normal use of EVs.

Under the premise that there is no big breakthroughs in EV-battery technology, heat pump has become the best solution to solve the problem of cruising range loss. The most prominent advantage is that heat pump can save nearly 50% of power consumption under heating conditions. Heating with a heat pump system greatly increases the EV driving range, offersing an energy-efficient alternative.

Representative electric vehicle models using heat pump system: Tesla Model Y, Audi e-tron, Roewe Ei5, Volkswagen e-Golf, BMW i3 etc.

Related Reading:

Vapor Injection Heat Pump System for EVs in Cold Regions

Service Object

NEV HVAC system not only provide for thermal comfort in the passenger compartment, but also is responsible for integrated vehicle thermal management (IVTM).

Control System

The control of air conditioning system in EVs is a little more complicated; the development of thermal management technology in electrified vehicles is based on that of conventional automotive air conditioners, while some technical parts are really different from traditional ones. For example, new HVAC system has more calibration conditions, and its control system is more complex than the control logic of traditional automobiles.

Software Development

The changes brought by EV development to the air conditioning system are multi-faceted. In addition to high-efficiency cooling and heating, the technical focus of future NEV thermal management system will be on safety, comfort, NVH, system operation economy, intelligent control, and ECM etc. The thermal management system will develop toward to “comfort+safety”, from the previous simple “hardware-based” technical direction to “soft and hard integration” one. Therefore, it requires enterprises and manufacturers to significantly improve software development capabilities.

Components Maturity

EV HVAC system integrates the functions of cooling, heating, and power battery thermal management. It also adds more new components application, such as

high efficiency 3 phase electric compressor (the design of ecompressor usually needs to consider both cooling mode and heat pump mode), plate heat exchanger for cooling modules, solenoid valves etc. But the single-component standards are still lacking, and need to be further improved.