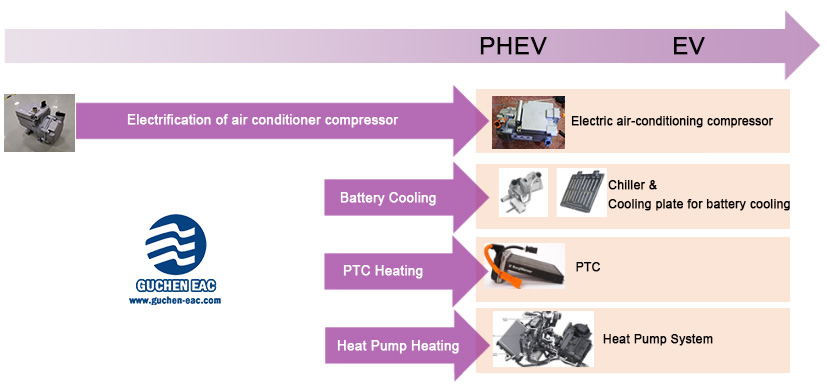

Heat Pump Air Conditioning System with Optimized Heating Efficiency for Electric Cars

The main obstacle facing electric cars today is the A/C system. As the core component of electric vehicle air conditioning system, there are higher technical requirements for electric motor driven compressors, which include:

◆ vibrate less and

quiet-running;

◆ High

energy efficiency;

◆ use

reliable precision engineered parts;

◆ Electronic components of the compressor should be

electromagnetically compatible with the whole vehicle;

◆ can be used for both

heating and

cooling an electric vehicle.

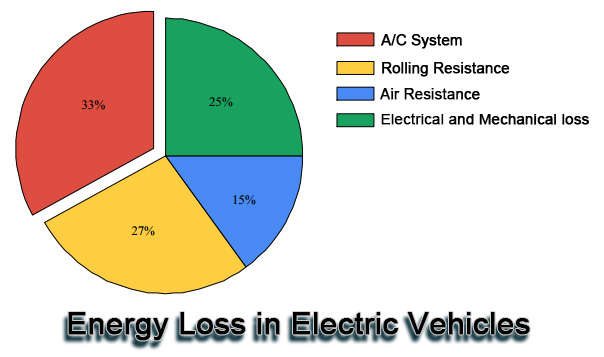

PTC heating: PTC is currently used as an additional electric heating device. The heating efficiency of PTC method is generally 70% to 90%, accounting for 20% to 30% of the total energy consumption of EV. Such a large amount of energy loss results in the greatly reduction of EV driving range.

Energy loss in electric vehicles

To minimize the energy consumption of an electric car when its A/C system is in use, a novel heating system should be designed and applied in automotive industry. Inverter two-stage compression low-temp heat pump air conditioner is such an innovative system, which can be used for both cabin cooling and heating in EVs.

Role of Compressor in Heat Pump System, and Technical Problems

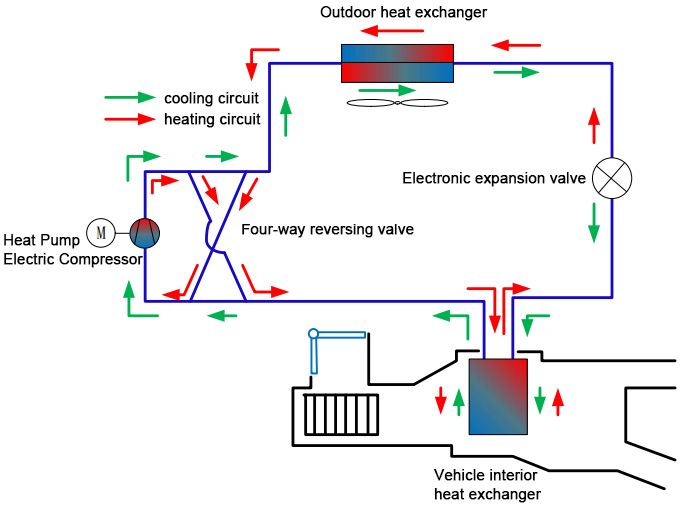

When heating, the low-temperature heat energy outside the electric car are transferred by heat pump system to high-temp thermal energy inside the vehicle.

Electric AC compressor will suck the low-pressure and low-temp refrigerant from the low-pressure end through four-way reversing valve, and compress it into high-temp and high-pressure superheated gas which will then enter the heat exchanger in the EV. The heat exchanger condenses and releases heat to the low temperature air in the passenger compartment air duct, thereby raising the temperature inside the passenger compartment.

electric vehicle heat pump system

However, electric vehicle air-conditioning compressors generally have major technical problems:

◆ no clearance start-up cannot be guaranteed;

◆ the need to greatly reduce noise;

◆ Heat pump heating has not been widely promoted and applied.

Due to the highly complex and changeable automotive driving environment, there is an urgent need to carry out research on the development and application of key technologies for electric vehicle air conditioning (heat pump) compressors. Such researches can help electric compressors adapt for working in difficult conditions and in a wider temperature range. It is a response to the rigid demand and strong energy-saving requirements of new energy vehicles.

Guchen EAC Heat Pump Electric Compressor

Guchen EAC combines two-stage compression with

inverter (variable frequency) technology and overcomes problems like low superheat vapor injection, two-stage compression profile design etc. We innovatively developed core technologies to optimize electric vehicle air conditioning (heat pump) compressor. The technologies include variable load smooth start-up, shrapnel-type axial flexible sealing, motor parameter recognition and real-time compensation drive, and motor space flux optimization and so on.

All the innovations significantly improve electric compressor performance, and reduce its operation noise. It solves heat pump heating problems at low ambient temperatures, promise start-up and smooth running of electric motor under extreme conditions, and widen the application range of heat pump air conditioning systems.

Features: the

heat pump scroll compressor adopts two-stage vapor compression technology, which separate gas and liquid through a flash evaporator to increase inlet and out air enthalpy difference. In the case of medium and low pressure, the air jet is mixed and cooled while being compressed; when the pressure is high, the compressed air volume is increased to achieve the purpose of improving the heating capacity in the low temperature environment.

Application: Guchen EAC heat pump compressors are mainly used in new energy vehicles, pure electric vehicles, hybrid vehicles, yachts, mining equipment, engineering machinery and truck conversion, etc. to meet the low-energy consumption, high-efficiency heating and vehicle thermal comfort of new energy vehicles in cold climate.

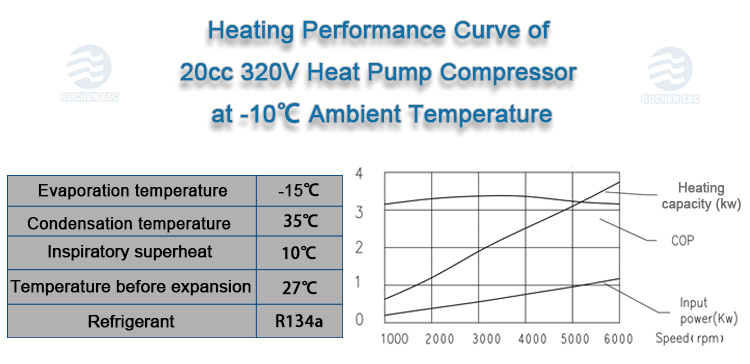

Coefficient of Performance: when the ambient temperature is -10℃, its COP value could be as high as 3.40; in an environment above -5℃, it saves more than 50% of energy compared with PTC heating; it is more energy saving and greatly improves the EV driving range.

heating performance of 20cc 320v heat pump compressor

Applicable to cold regions: it can meet the heating demand of -20℃ to -25℃ ambient temperature, suitable for cold climates;

High comfort: Compared with the PTC heating method, outlet air temperature rises quickly; the use of temperature control to stabilize the air outlet makes driving more comfortable.