The key aspects of R290 system design focus on safety and performance / energy efficiency:

1.Safety

In highly integrated modular systems, the overall structure should be compact, with smaller fluid passages and reduced flow volumes. Connections between heat exchangers and electric compressors must be of higher quality, and the sealing designs of joints should be further reinforced.

2.Performance and Energy Efficiency

The water-side internal volume should be minimized to reduce thermal inertia at the outlet. Critical components should be thermally insulated. The intrinsic performance of key components—such as the compressor, flow channel plates, and plate heat exchangers—should be enhanced.

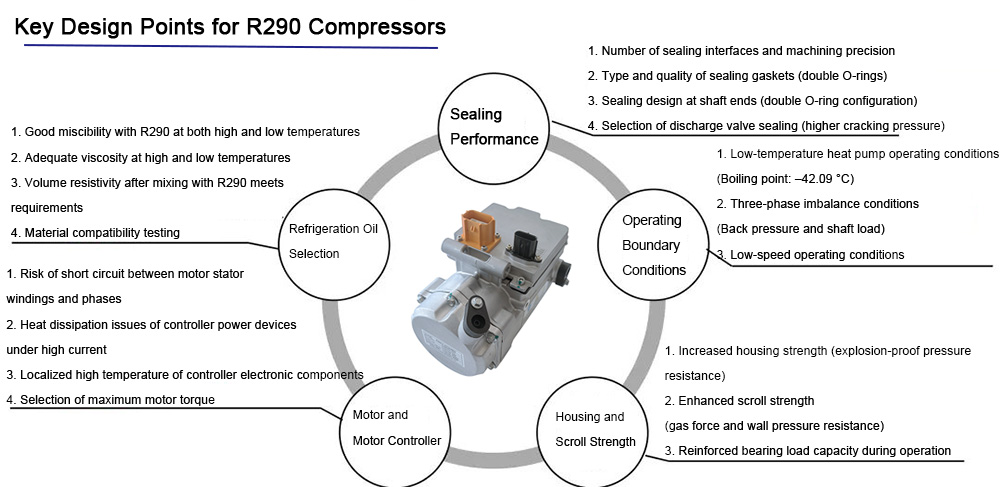

1.Sealing Performance

Traditional compressors, whether four-terminal or five-terminal designs, have multiple sealing interfaces. For R290 electric compressors, the stationary scroll can be integrated internally to reduce the number of exposed sealing surfaces, while higher flatness accuracy of the sealing faces is required.

For gasket seals or O-ring seals at joints, Guchen considers splitting a single large O-ring into a dual-ring configuration.

For

electric vehicle ac compressors, in many cases the pressure relief valve can be eliminated. If a relief valve is required, the opening pressure threshold should be significantly increased.

2.Operating Envelope

R290 has a very low boiling point of −42 °C, making it well suited for ultra-low-temperature heat pump applications. Under triangular cycle and bypass cycle operating conditions, the peripheral pressure of R290 can increase significantly. Therefore, attention must be paid not only to axial forces and back pressure within the electric compressor, but also to the dynamic loads on bearing subcomponents.

Under low-speed operating conditions, focus should be placed on the motor’s low-speed driving capability. In addition, at low speed and low mass flow rates, the refrigeration capacity per unit mass flow is relatively low, so thermal management of power electronic devices must be carefully considered.

3.Strength of the Housing and Scrolls

The compressor housing must be designed to withstand increased discharge pressure. Some rear covers require additional reinforcement in both thickness and structural design.

For the orbiting and fixed scrolls, scroll tooth strength should be enhanced, including changing from variable wall thickness to uniform wall thickness. Connection fillets, tail sections, and support areas may also require reinforcement.

4.Motor and Power Electronics

Risks such as inter-turn short circuits and phase-to-phase short circuits in the motor stator of the electric compressor must be considered. Local overheating and over-temperature conditions of power electronic components also require special attention.

As operating drive torque demand increases significantly, the motor’s continuous operating capability must be enhanced.

5.Lubricating Oil Compatibility

First, the lubricating oil must have good high- and low-temperature compatibility with R290, with particular attention to potential phase separation at different temperatures. Since R290 has relatively good intrinsic volume resistivity, the selection range of lubricating oils is broader; it is not mandatory to use PVE or POE oils, and conventional oils used in original ambient-temperature electric compressors may also be applicable.

Finally, after mixing the lubricating oil with the refrigerant, additional compatibility tests should be conducted on compressor rubber components, plastic parts, and coating materials.