What is Pre-charge Circuit?

In high-voltage system (100V+), there is a large number of capacitive loads. At power on, as the initial voltage across the capacitor is zero, charging the capacitors will lead to significant inrush current. Especially when the filter capacitor with larger capacity is used, the inrush current can reach more than 100A. Such large inrush current exceeds the nominal load current, and often cause the burn-out of power system or closing switch contacts. It will result in electric shock to the entire high-voltage circuits.

For this reason, it is necessary to pre-charge the DC high voltage power system to limit inrush current at system power-up.

---------------------

Related Reading:

What is High Voltage Interlock Loop?

---------------------

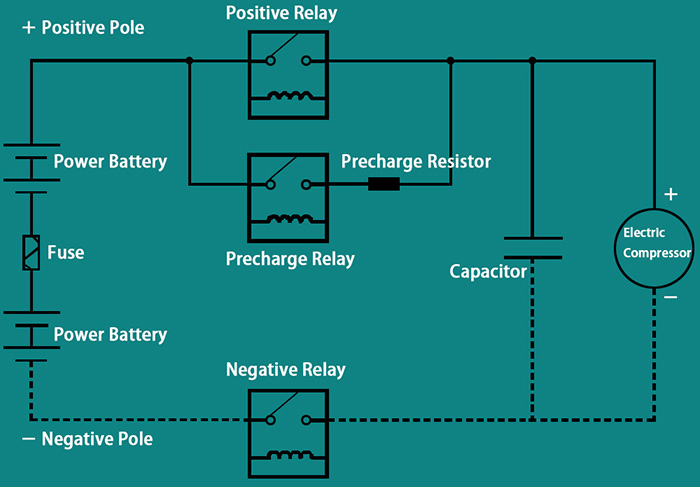

Pre-charge Circuit as shown in Figure 1.

Figure 1. High-voltage circuit schematic - Precharge circuit design in EV HV system

The pre-charge control circuit is composed by a relay (precharge contactor) and a resistor. These two components are wired in and installed on the positive leg, in parallel with the main relay. We can see that, in a high voltage system, there is typically a DC link capacitor, and three high-voltage relays, namely, main positive relay, main negative relay and pre-charge relay.

How Pre-charge Works?

At system power on, the controller in battery management system (BMS) disconnects the positive contactor first, and then powers the pre-charge units including

pre-charge contactor and

precharge resistor. The inrush current flows entirely through the pre-charge circuit, to slowly charge the downstream capacitor. When the capacitor voltage rise close to battery voltage, the controller controls the positive contactor to be turned on (all of the system current now passes through the main relay), and then cuts off the pre-charge contactor. In this way, normal HV system operation is achieved.

◆ The

precharge resistor acts as a current limiter.

◆

The function of the pre-charging contactor is to effectively protect the downstream capacitance, insurance, and DC contactor from damage; At system power up, the inrush current may be large enough to destroy the capacitor. The instantaneous peak power also may cause danamge to the DC contactor and other switching devices. The pre-charging contactor is necessary to protect the system from damage, and increases system reliability.

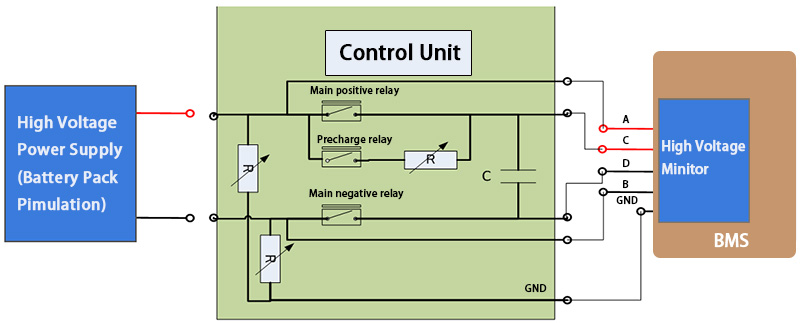

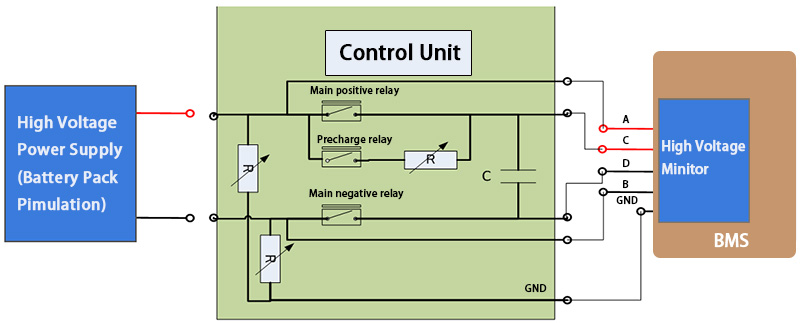

Figure 2. Schematic diagram of High Voltage Simulation Box

Figure 2. Schematic diagram of High Voltage Simulation Box

Why Pre-Charge Circuits are Necessary in High-Voltage Systems

When power is first applied to the HV system, a high surge current is induced. Failure to manage the surge current can lead to stress and damage to electrical power system. Therefore, the high voltage systems need to be pre-charged with a controlled current.

● It minimizes the peak current out from the power source by slowing down the input voltage.

● It prevents cables, connector or fuses from damage by implementing a pre-charge resistor and a contactor to control inrush current.

● High voltage pre-charge units prolong the lifespan of the main relays and other electrical components dramatically by charging the DC link capacitor before the main contactor switches on.

● Pre-charge circuits are widely used in EVs such as motor control unit, charging system, air condition system, BMS etc.

For that reason, pre-charge circuits are necessary in high voltage systems in electric vehicles.

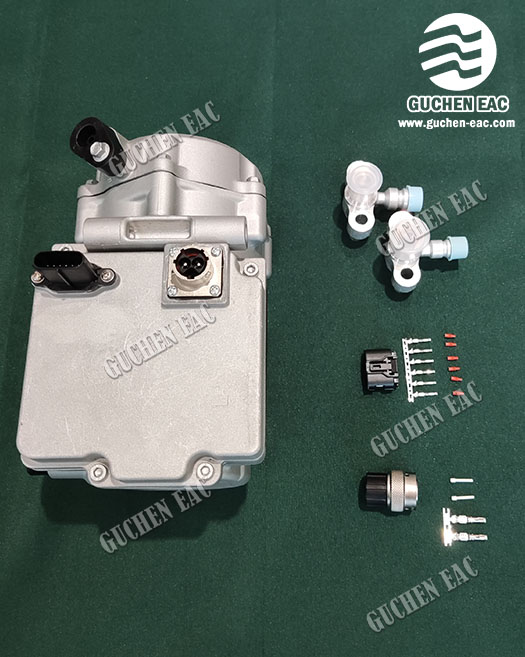

The a/c compressor on the electric vehicle is directly operated by the power from high voltage battery. The current of the compressor controller increases instantaneously the moment the driver or passenger push the A/C button. High Instantaneous Current may cause great damage to the power battery, e-compressor and fuse. Therefore, some of our HV compressor customers (mostly commercial vehicles) will require Guchen EAC to provide a pre-charge resistor module when

producing electric vehicle compressors, to reduce the impact of starting current and protect the normal operation of compressors.

Pre-charge resistor is to meet the pre-charging of electric compressor during the power-up procedure.

◆ small size

◆ IP68 high protection level

◆ high withstand voltage

◆ high security

◆ 100VDC - 800VDC high voltage range

It integrates compressor energy storage protection circuit, reverse voltage protection circuits, residual voltage discharging circuit, and capacitive load precharge circuit etc. By reasonable logical judgment and control, the protection of the electric compressor can be well realized.

Guchen HV electric compressors have built-in pre-charge circuits, which protect the compressor units in advance and ensure its safe operation even if the compressor is not connected with the high voltage precharge control circuits of the electric vehicle.

For more detailed information, please feel free to mail to

compressor@guchen.com