By 2027, the electric vehicle market is expected to reach more than 100 million units. In order to achieve ambitious goals like this, the industry must continue to improve the performance of battery packs and cooling systems with lightweight and efficient solutions.

The current trend in electric vehicles is toward higher energy density batteries that can deliver more power while reducing weight. However high energy density also increases thermal stress on the cells which can lead to thermal runaway reactions if not properly managed through

adequate heat transfer management strategies.

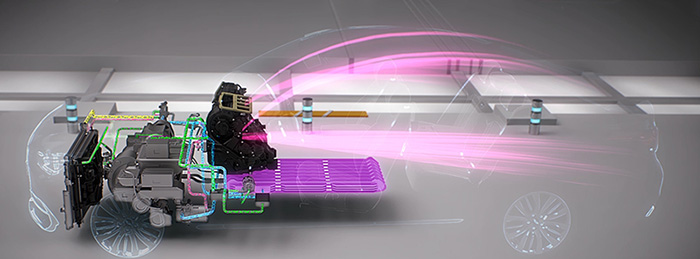

Overall Electric Vehicle Thermal Management System

An electric vehicle thermal management system is responsible for the cooling of all the key components in an electric vehicle. It must be able to control the temperature of each component throughout its entire operating range, while also ensuring that there are no serious adverse side effects resulting from these temperatures in relation to other parts of the car.

Overall vehicle thermal management system includes the cabin air conditioning,

battery pack cooling/heating, and other vehicle components (power electronics and electric motor) cooling.

The Necessity of Cooling Down Battery Pack, for Safety's Sake

The battery pack is the largest heat-generating component in the electric vehicle. It is also the most critical because it determines how far a vehicle can travel and at what performance level.

To sustain high energy density and improve power density, batteries are compactly packaged into an enclosure that may or may not have active cooling. In either case, proper management of battery temperatures is essential for maintaining its operational performance and extending service life.

What's more, battery pack cooling will enhance of performance of electric vehicles. By efficiently cooling the battery packs, we can reduce the overheating risk and improve their range and performance.

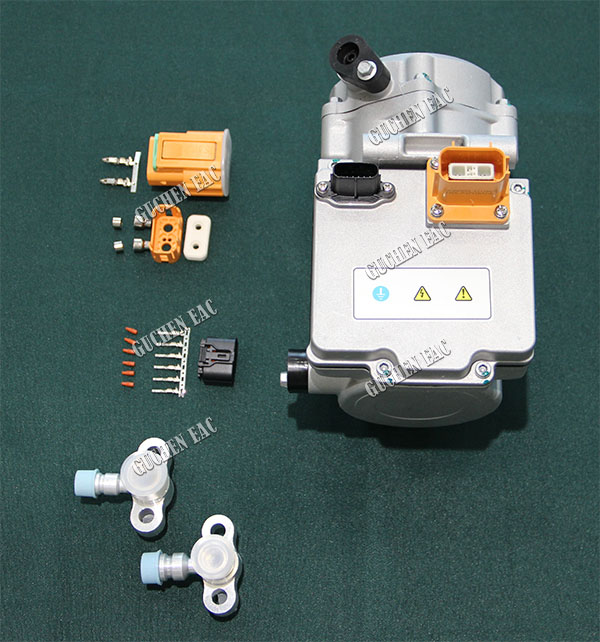

Battery Cooling can be Achieved by Using a DC Electric Air Conditioning Compressor

HV AC compressors are specifically designed for use in electric vehicles, for cabin cooling and heating. Besides that, they are reliable to cool EV batteries.

Guchen electric compressors will assist in cooling down your battery pack quickly when it gets too hot or overcharged during charging/discharging cycles. Taking

Guchen 800v electrically-driven compressor for example, it is mounted in the refrigerant loop of EVs, also a component of battery coolant loop. It is highly efficient and can maintain optimal temperatures for long periods of time. The 800v a/c compressor works by circulating cool air around the batteries, which helps to remove heat from the battery coolant loop. The cool air is then circulated back into the battery chamber, where it helps to keep the batteries cool and dry. Guchen 800v compressor is a valuable addition to any electric vehicle.

With the increasing number of electric cars in use, it is clear that a DC electric air conditioning compressor is an important part of the system. This technology can be used to cool down battery packs and keep them at safe operating temperatures. As more companies start manufacturing these compressors, we will see more options available for EV owners who want to stay cool during hot weather rides.

The importance of battery pack cooling will continue to escalate as the evolution of battery cooling systems continues to progress at an accelerated pace. In the future, we will see more advanced thermal management solutions for electric vehicles based on immersion cooling.