How Important is a Vehicle Air Conditioning Compressor?

The compressor is a key component of a vehicle's air conditioning system, also the most expensive part. It is one of the decisive factors affecting the performance of the A/C unit. The HVAC compressor is the heart of the whole refrigeration system, acting as a circulation pump to compress and raise the refrigerant pressure.

Without it, the entire HVAC system won’t be able to perform normally to remain passengers cool/warm inside the commercial vehicles.

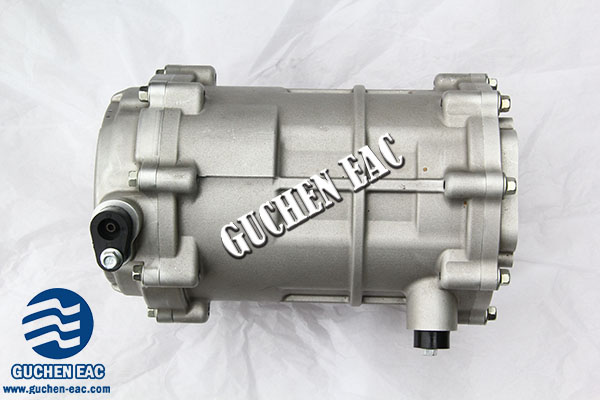

Piston compressor or screw compressors are widely-used unit in traditional bus A/C systems. They are mechanically driven by the bus engine. Nowadays, the global focus more on "Green" vehicle air conditioning system. One significant area of contribution is the electrification of compressor technology. Most of the new energy bus air conditioners use horizontal

inverter type electric scroll compressor.

Electric Compressor for EVs

For battery electric vehicles (BEV), an electric compressor is a must-have for its electric air-con systems. Unlike conventional belt-driven compressor that works by using the energy from the vehicle engine, electrically-driven compressor is powered by direct current from a rechargeable battery in EVs.

Electric vehicles are based on high-voltage battery systems, such as +350V. Correspondingly,

high voltage electric compressors are innovative designed and manufactured to match the EV battery voltage, and greatly pushing the development of energy-efficient electric air conditioning systems.

Nowadays, energy efficiency has been a key global focus. In auto industry, there is simply no credible way to reduce carbon-dioxide emissions without increasing electrification in automotive powertrains, meaning electric vehicles and hybrid electric vehicles. In 2019, the electric vehicle market made big gains. It is estimated that there are more and more automotive manufacturers electrifying their fleets in the coming decade.

We can be sure that the future is definitely electric.

With promising future of electric vehicles, the future of electric compressor is also believed to be brighter than ever due to the following 3 factors:

◆ Greener

Electric drive compressor helps reduce carbon footprint, seen as playing a crucial role in zero-emission ecosystem. The latest innovations in electric compressor inverter technology play a prominent role in dealing with climate change, and creating the demand for greener lifestyle. It will greatly benefit in reducing fuel consumption to change the power source for compressor system to the electrically driven.

◆ Technologically superior to belt-driven compressor

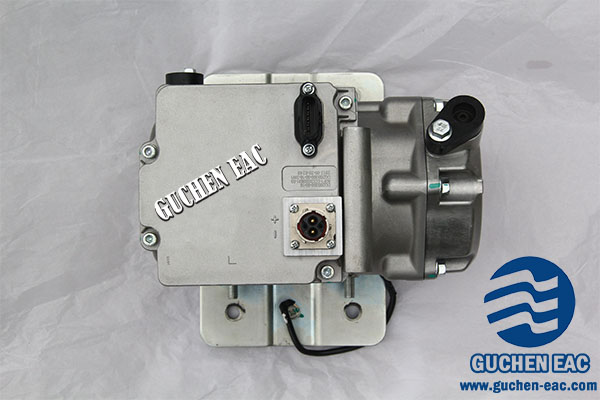

Electric compressor adopts a) the most advanced inverter technology; b) brushless electric motor; c) hermetic design; d) heat pump system. all the technologically advanced design enable it offer enhanced durability and greater efficiency.

◆ Quieter Operation

Electric compressor is driven by brushless electric motor. Its operation is vibration-free, and exceptionally quiet. The low noise capabilities make electric compressor ideal for 24 hour city applications. The noise-free compressor meets the increasing requirement to reduce noise pollution. Electric AC compressor will definitely be a good investment in a bright future.

Top Recommendation, Associated Electric Compressors

| Model |

20cc |

27cc |

| Speed range |

1000~6000rpm |

| Rated voltage range |

DC320V/DC200 - 400V (can be adjusted according to customer's specific requirements) |

| Operation Environment Temperature (℃) |

-10~+65 |

| Refrigerant |

R134a |

| Oil Type |

POE OIL RL68H |

| Max cooling Capacity |

4500W |

6000W |

| Weight |

6.3kg |

6.3kg |