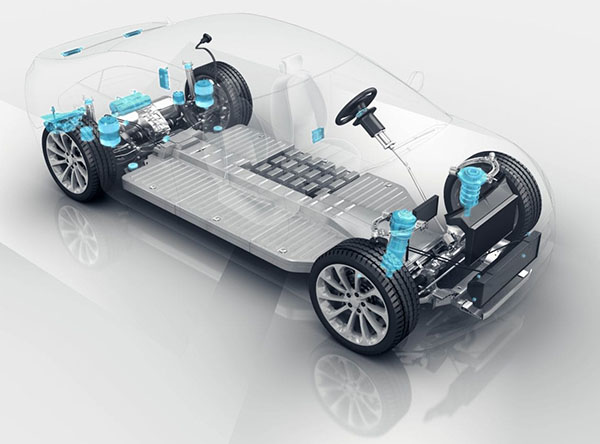

Electric vehicles, as the new generation of automotive industry, are earning great popularity among global investors. With today’s growing focus on low energy consumption and sustainable transportation, electric vehicles are quickly becoming the future of the automotive industry with more people investing in new energy vehicles.

Favorable Market Forces have Aroused Heated Discussion

Along with rising market focus, electric vehicles must face many new tough issues, such as NVH (noise, vibration and harshness) issues which ICE-vehicles have faced until today. NVH development has attracted great attention. Torque ripple, high-frequency tonal noise from the electric motors, lightweight design and reduced materials in EV design, all the parameters become electric vehicle noise, vibration and harshness challenges.

NVH reduction caters to automotive consumers’ expectations on ride comfort. Vibration reduction and noise control have been one of the most important goals in EV design. Sound package schemes, multi-body dynamics, optimizing HVAC noise system performance, polyolefin solution ...... EV manufacturers, engineers and designers are seeking suitable NVH solutions for a smoother, quieter driving experience.

This article discusses about the NVH solution in the electric vehicle recently launched by Vibracoustic.

Electrically-driven Compressor Decoupling Solution

In December, 2020, Vibracoustic launched the effective solution that will greatly contribute to overcoming many NVH challenges and help EV engineers change the sound quality.

It is called as

eCompressor Decoupling Solution.

Background Information:

electric compressor generates more NVH than internal combustion engine, the reason of which is that electric compressor experience much greater loads when circulating the coolant to manage EV cabin temp.

Besides that, electrically-driven compressor is usually working at very different speed ranges (for example,

inverter type electric compressor), orders and excitation directions, resulting in more NVH.

How to Optimize NVH Performance of EVs: By utilizing soft elastomer mounts. NVH problem can be tackled by optimizing the bracket and mounting assembly system performance.

Solution Provider: Vibracoustic, a Germany company, the world leader in automotive NVH solutions

Application: it is an innovative solution for electric compressor, available both pure-electric vehicles and plug-in hybrid ones.

How it achieves:

◆ By optimizing bearing stiffness and position, Vibracoustic achieves the goal of minimizing electric compressor noise while stationary during fast charging;

◆ With substantive test on the entire mounting system, it is possible for Vibracoustic to develop & manufacture bracket and mounting assembly, thus reducing the noise and vibration inside the EVs during motion.

◆ By conducting extensive elastomer simulation process, Vibracoustic tried to determine the ideal rubber compound, and then adjusting its geometry via proprietary software for minimum wear and maximum service life.

Electric compressor decoupling system is just one of the novel NVH solutions automotive engineers work out now. It enables to isolate the vibration and noise from electric air conditioner compressor, thus improving NVH performance.

There are still many challenges for new energy vehicles.

Guchen EAC appreciates all the efforts that manufacturers and engineers have made to make our riding a lot more peaceful and comfortable.