“Could you send me the datasheet and drawing/CAD model for your 800V air conditioner compressor please?”

--Koenigsegg AB

Guchen Started First Collaboration with Koenigsegg on August, 2022

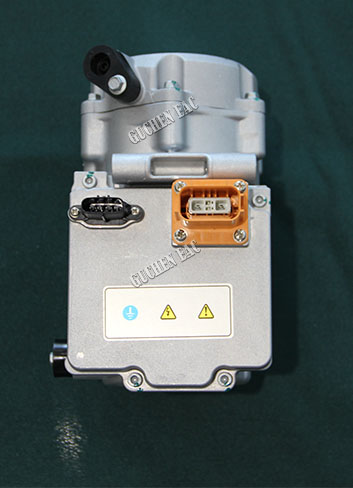

Since the noval 800V compressor was launched on March, 2022, it has received the attention of so many famous EV manufacturers around the world such as Terraline Trucks, Cummins, Schaeffler Group, AVL, Lotus cars and Koenigsegg. All of them regarded the 800V product as a perfect option on their DC compressor options, and find Guchen a stable and reliable supplier on

electric ac compressors.

Koenigsegg showed its great interest in an AC compressor with a nominal voltage of 800V on August 9th, 2022. Guchen 34cc 800v compressor is with a max cooling capacity of 6.1KW, which can perfectly meet Koenigsegg’s expectations.

◆ “What validation and endurance testing has been completed?”

Each Guchen compressor undergoes a series of comprehensive performance tests before it goes online, including but not limited to the following:

1)Basic performance verification: Volume flow, exhaust temperature, noise sound pressure level, vibration intensity, input specific power;

2)Environmental adaptability: high and low temperature adaptability, vibration durability, corrosion resistance (salt spray), heat and humidity resistance, protection level;

3)Safety: withstand voltage strength, ground resistance, insulation resistance, flame retardant characteristics, drive motor temperature rise;

4)Reliability: 10000 hours endurance test, overload resistance, electromagnetic compatibility (EMC).

◆ “Do you have them on any production vehicles?”

Yes, we have applied the

800V electric compressor in the production vehicles. By precisely regulating compressor speed and refrigerant flow based on real-time cooling demands, it minimizes energy wastage and ensures optimal performance at all times. This translates to extended driving range for EVs and improved fuel efficiency for hybrid vehicles, aligning perfectly with the industry's sustainability goals.

The integration of the 800V electric compressor in production vehicles showcases its real-world applicability and performance under diverse conditions. From compact city cars to luxury electric SUVs, Guchen's compressor has proven its mettle, delivering consistent cooling performance while reducing overall system weight and complexity.

◆ “Manufacturing capabilities”

With a remarkable capacity to produce 200,000 units annually, Guchen Industry has firmly established itself as a leader in e-compressor sector, setting high standards for quality, reliability, and innovation.

Equipped with cutting-edge machinery, automated assembly lines, and stringent quality control measures, Guchen ensures precision and consistency in

every electric automotive ac compressor produced. Modern manufacturing techniques and a focus on lean practices further enhance efficiency, minimizing lead times and optimizing resource utilization.

Guchen Industry's ability to produce 200,000 units annually is not just a testament to its current capabilities but also underscores its scalability and adaptability. Whether it's meeting growing market demands or customizing products to meet specific client requirements, Guchen's manufacturing processes are designed for flexibility without compromising on quality or efficiency. This agility enables Guchen to stay ahead in a competitive market while catering to diverse customer needs.

Guchen Team Customized Real-time Temperature Feedback for Koenigsegg’s Second Order

When it comes to high-performance vehicles like those from Koenigsegg, every component must not only meet stringent standards but also be tailored to specific performance demands. For their second order with Guchen Industry, Koenigsegg team required a real-time temperature feedback system that could precisely monitor and adjust compressor operations according to dynamic driving conditions and performance demands.

Guchen Industry's team of engineers and technicians embraced the challenge presented by Koenigsegg's requirements. Leveraging their expertise in electric compressor technology and data analytics, they developed a customized real-time temperature feedback system specifically designed to integrate seamlessly with Koenigsegg's high-performance vehicles. This system not only reports compressor temperatures on CAN in real time but also derate the AC compressor before it overheats, specially if no overheat error is reported as per the CAN database, enhancing overall reliability under varying loads and environmental conditions.

By understanding and meeting specific performance demands,

Guchen EAC not only fulfills customer expectations but also drives innovation and sets new standards for performance and reliability in high-performance vehicles. This partnership underscores the importance of tailored solutions in the ever-evolving landscape of automotive engineering and technology.