In the rapidly evolving landscape of electric vehicle (EV) technology, effective thermal management is crucial for optimizing battery performance and ensuring longevity. At Guchen Industry, we are proud to highlight the successful applications of our

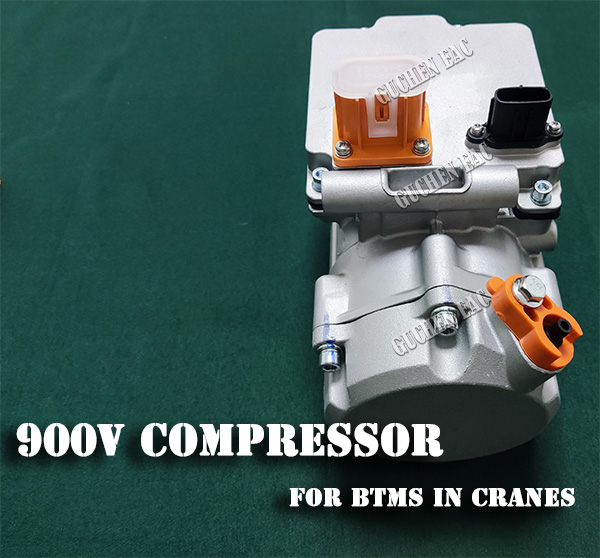

900V electric compressors, specifically the GC27A900 and GC34A900 models, in 3KW and 5KW battery thermal management systems designed for cranes. These case studies not only demonstrate the high efficiency and versatility of our products but also reinforce our commitment to quality and innovation in the EV sector.

Project Background

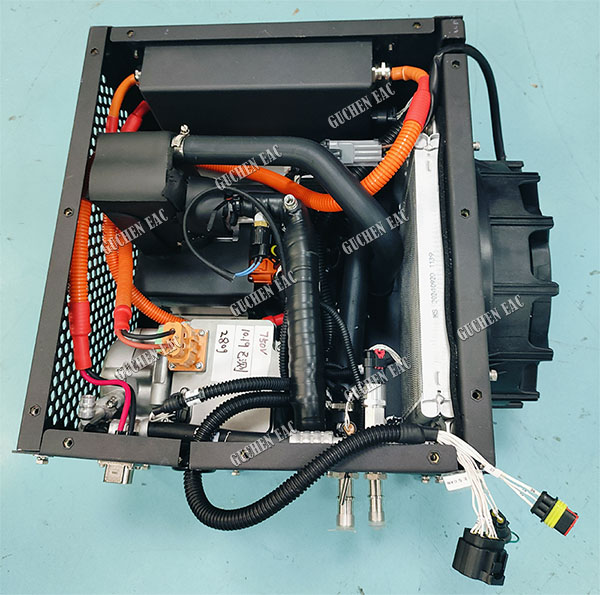

Our customer, a manufacturer of electric construction machinery, is looking for a small power BTMS in the range of 2kW to 3kW that can operate at voltages up to 900V. Their specific requirement focuses solely on battery cooling using liquid, with no additional HVAC functionalities needed. They approached us to inquire about our offerings, specifically whether Guchen Industry supplies complete BTMS solutions or only the compressors. We are pleased to confirm that we provide a complete BTMS solution that integrates our

high-efficiency electric compressors, specifically tailored for their cranes.

Project Overview

1. GC27A900 in a 3KW BTMS

Our GC27A900 electric compressor was integrated into a 3KW battery thermal management system designed for a prominent electric crane manufacturer. The project aimed to enhance the thermal performance of the battery, particularly under varying operational conditions. Additionally, the system includes a 3kW PTC heating element, which warms the battery during cold weather, ensuring optimal performance regardless of environmental conditions.

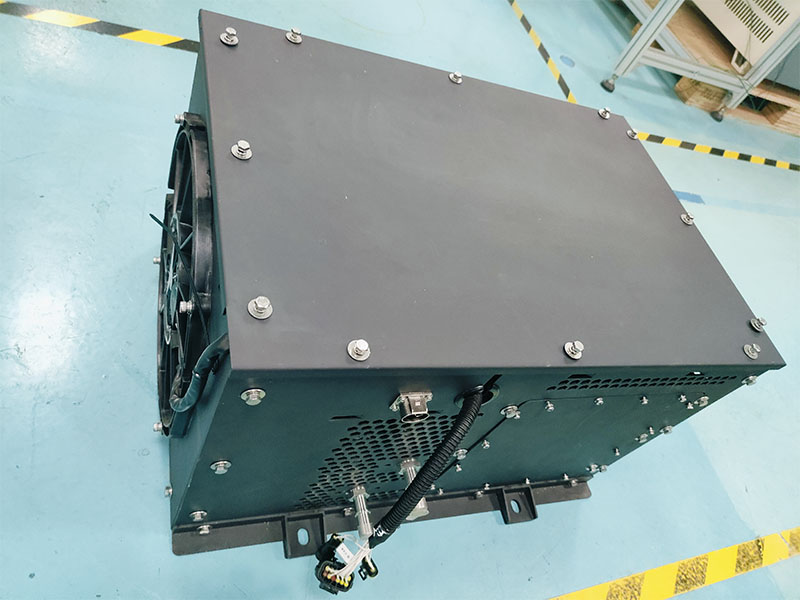

Challenges Faced: The primary challenges included managing tight space constraints within the crane's design, necessitating a compact and efficient compressor. Additionally, selecting the appropriate quick disconnect connectors for the liquid connections was critical to ensure optimal performance and reliability in the cooling system. The project also faced a limited budget, which required our engineering team to design a BTMS that balanced appropriate sizing with high quality and cost efficiency.

Implementation: The GC27A900 compressor, with its advanced design and high efficiency, was chosen for its ability to provide consistent cooling performance. Its lightweight structure facilitated easy integration into the crane’s design, minimizing space constraints without compromising functionality.

The implementation of the GC27A900 led to a significant improvement in thermal regulation. Post-implementation testing showed a temperature stabilization of the battery pack within the optimal range, even under high load conditions. This ensured improved battery longevity and performance, solidifying the manufacturer’s trust in our compressor technology.

2. GC34A900 in a 5KW BTMS

For the 5KW battery thermal management system, our GC34A900 model was selected, focusing on enhancing cooling capabilities for larger battery systems used in high-performance electric cranes. The GC34A900 compressor boasts a cooling capacity of 5670W at 6000 RPM, making it ideal for meeting the customer’s substantial battery cooling requirements.

Challenges Faced: The larger battery system required a more robust thermal management solution capable of dissipating heat efficiently while maintaining energy efficiency. The manufacturer needed a solution that would not only cool the batteries but also contribute to the overall energy efficiency of the vehicle.

Implementation: The GC34A900 compressor was chosen for its superior cooling capacity and efficiency. Its compatibility with 900V systems allowed for seamless integration into the existing architecture of the battery management system. The compressor was equipped with advanced control algorithms, optimizing its operation based on real-time thermal data.

The project yielded impressive outcomes, with the GC34A900 achieving a 20% improvement in thermal efficiency compared to previous systems. The enhanced cooling capabilities contributed to better battery performance, with a noticeable increase in the vehicle's range and reduced energy consumption. The positive feedback from the manufacturer highlighted the compressor's reliability and efficiency.

Certifications

To address our customer's concerns, we are proud to inform them that our compressors hold CE and ISO9001 certifications. These certifications underscore our commitment to quality, safety, and compliance with international standards, ensuring that our products meet the rigorous demands of the electric construction machinery industry.

Benefits of Using 900V Electric Compressors

The successful implementation of the GC27A900 and GC34A900 compressors in these projects exemplifies the advantages of utilizing high-efficiency 900V electric compressors in battery thermal management systems:

- Enhanced Efficiency: Our electric high voltage a/c compressors are designed to operate efficiently at high voltages, leading to lower energy consumption and improved vehicle range.

- Versatility: The adaptability of our compressors allows them to be used in various applications, from cranes to high-performance electric vehicles.

- Reliability: With rigorous testing and quality assurance processes, our compressors are built to withstand the demands of electric vehicle operation, ensuring long-term reliability and performance.

At

Guchen Industry, we continue to push the boundaries of technology in the electric vehicle sector, ensuring that our products not only meet but exceed industry standards. As we look to the future, we remain committed to developing solutions that enhance battery performance and contribute to the broader adoption of electric vehicles worldwide.