Electric air conditioning compressors are vital components in modern vehicles and off-grid setups, providing efficient cooling solutions. However, understanding their wiring and control methods can be challenging, especially when choosing between 3-speed rotary switches and Pulse Width Modulation (PWM). This guide will explore both methods and provide practical wiring diagrams to help you set up your compressor effectively.

The 12V electric compressors operate using a DC 12V power source and require proper wiring to function efficiently. As for the speed regulation method, there are two main types: 3-speed or PWM models, depending on your application’s needs. While the 3-speed rotary switch offers simplicity, PWM enables precise speed control, often necessary for advanced applications like electric vehicles (EVs).

The 12V compressor comes with three cables: one for battery positive (+), one for battery negative (-), and a signal cable with five wires in different insulation colors: white, red, black, blue, and green. When wiring the compressor, the main difference between PWM and 3-speed control lies in the wiring methods of the signal line. Below, we detail how to set up each method, accompanied by figures showing the wiring configurations for both control types.

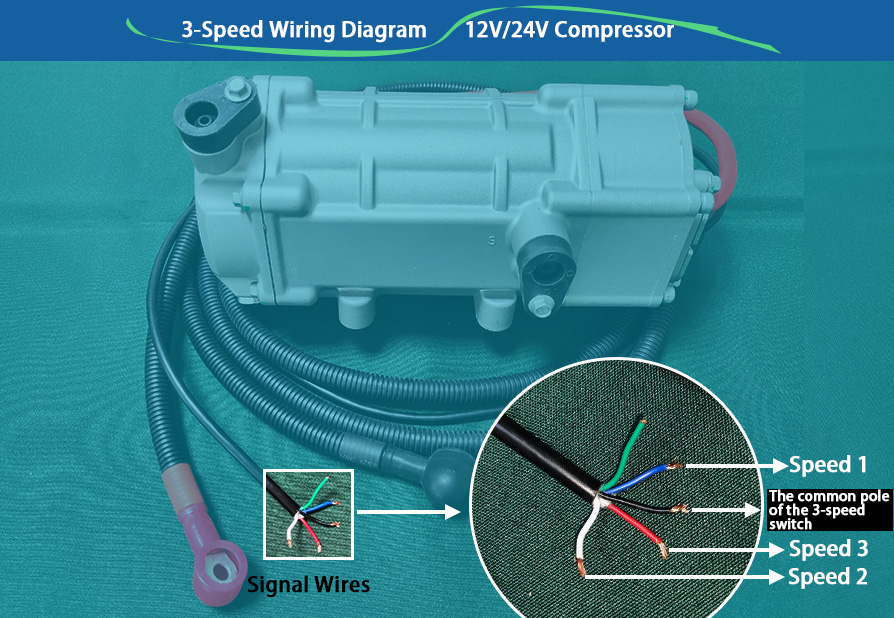

Wiring the Compressor Using a 3-Speed Rotary Switch

The 3-speed rotary switch allows users to select between high, medium, and low speeds. It is ideal for straightforward applications where precise control isn’t critical.

Wiring Diagram

The basic wiring setup includes:

- A power source connected to the switch.

- Speed control wires from the switch to the compressor.

Step-by-Step Instructions

- Identify Terminals: Locate the high, medium, and low terminals on the rotary switch.

- Connect Wires: Link the terminals to the corresponding speed control inputs on the compressor. Specifically, connect the blue, white, and red wires to Speed 1 (low speed), Speed 2 (medium speed), and Speed 3 (high speed), respectively, while the black wire serves as the common pole of the 3-speed switch. The three fixed speeds correspond to 2500 RPM, 3500 RPM, and 4000 RPM (revolutions per minute).

- Power: Attach the power wire to the switch’s input.

- Test the System: Ensure the switch correctly toggles between speed settings.

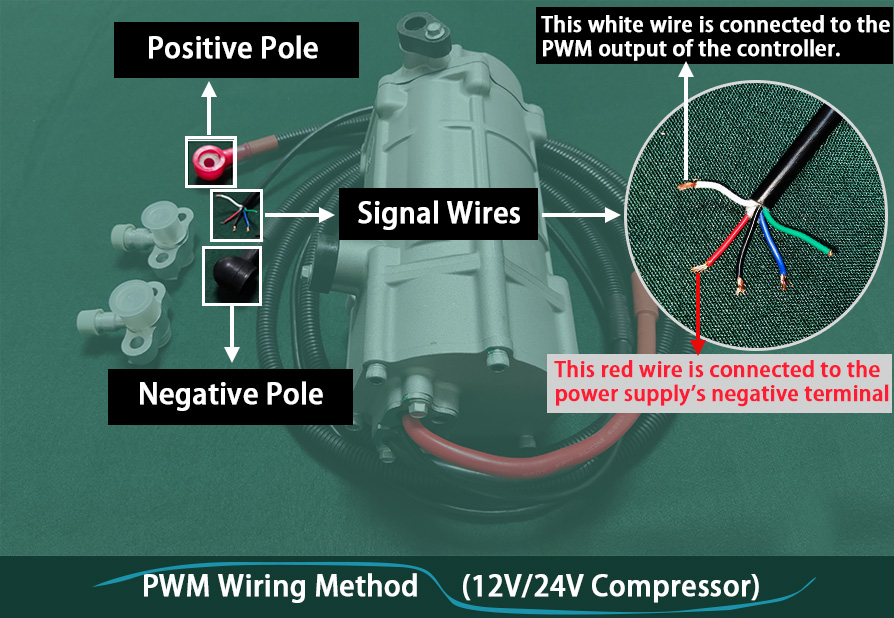

Wiring the Compressor Using PWM

PWM provides precise control over compressor speed by varying the signal’s duty cycle. This method is preferred in systems requiring variable cooling capacity.

Wiring Diagram

The setup involves:

- A PWM controller.

- Signal wire connecting the controller to the compressor.

- Power connections.

Step-by-Step Instructions

- Set Up the Controller: Connect the PWM controller’s power terminals to the power source.

- What does the Signal Wire Connect to? Link the white wire from the compressor’s signal cable to the PWM controller. The red wire connects to the power supply’s negative terminal.

- Adjust Parameters: Configure the PWM frequency and duty cycle based on the compressor’s specifications.

- Test Operation: Verify that the compressor speed adjusts as the duty cycle changes.

Key Considerations

Ensure the PWM signal voltage matches the compressor’s requirements.

Improper settings can affect performance or damage the compressor.

FAQs

1. How much current does the GC20A12 compressor pull?

The current draw varies based on operating conditions. Refer to the product datasheet for maximum ratings.

2. Is a controller required for the compressor?

Yes, most compressors require a controller for speed regulation. The signal wire connects to either a vehicle’s ECU or a standalone PWM controller.

3. How do I control the

low voltage ac compressor’s speed using PWM?

Set the PWM controller’s frequency and duty cycle as specified in the compressor’s manual. The compressor starts at a low level, and its speed can be adjusted by varying the PWM duty cycle. A 10% duty cycle corresponds to 1000 rpm, while a 90% duty cycle corresponds to 6000 rpm. Linear speed control is achieved between 10% and 90%.

PWM Signal Generator

4. What is the cost and shipping for compressors?

Pricing and shipping vary. Contact our sales team for detailed quotes.

Proper wiring is essential for optimal

electric compressor performance. Whether you choose the simplicity of a 3-speed rotary switch or the precision of PWM control, following the correct wiring procedures ensures efficiency and safety. For technical support or additional inquiries, contact our team today.